Custom springs are the unsung heroes of modern product design, quietly performing vital functions that often go unnoticed by the end-users. Whether it’s in the suspension of a car, the hinges of a laptop, or the mechanisms inside medical devices, springs play an essential role in ensuring proper functionality.

Let’s explore how custom springs contribute to the success of countless products. From their fundamental characteristics to their diverse applications in various industries, we uncover the multifaceted significance of springs in product design.

The Fundamental Role of Custom Springs

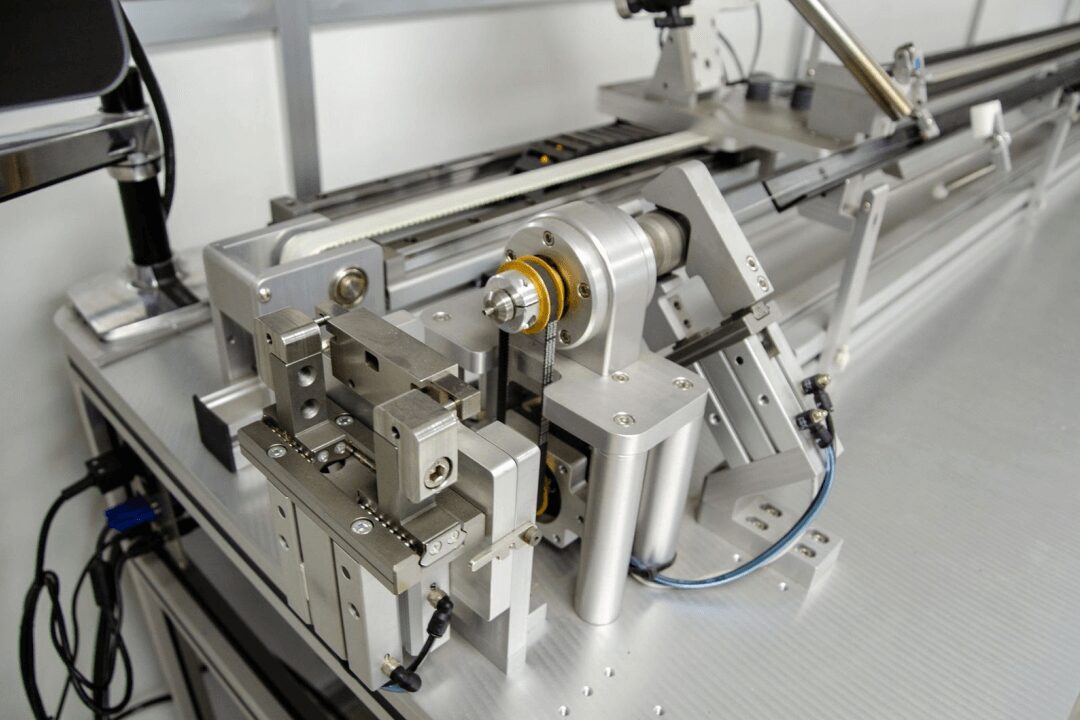

Springs can play a critical role in how a product performs in many ways, like how it manages energy, such as vibrations and shocks. If common springs are not right for your project, here at Western Spring, we can help you design the perfect custom spring. While we have many standard spring designs, we also pride ourselves on being able to design the right springs to meet the specifications provided by our customers.

Elasticity and Deformation

At the core of spring functionality is their unique ability to deform elastically under a load and then return to their original shape once the load is removed. Understanding this fundamental property is key to understanding how springs work and why they are critical in many applications and products. When we help customers design the perfect spring, we account for the maximum load and deflection.

Storing and Releasing Energy

As mentioned above, springs act as energy storage devices. They accumulate potential energy when compressed or stretched and then release it when the force is removed. The mechanics of how springs store and release energy have critical implications for different designs.

Providing Force and Motion

Springs are also essential for providing force and motion in a controlled manner. They allow for controlled acceleration, deceleration, and motion control. Essentially, they help to facilitate force and motion in various products and applications.

How Springs Offer Mechanical Support

From bearing heavy loads in automotive suspension systems to maintaining structural stability in construction equipment, springs offer mechanical support in diverse ways. This section explores the load-bearing capabilities and structural stability that springs can provide.

Motion Control (Damping vibrations, Absorbing shocks)

In applications like automotive and machinery, controlling motion and damping vibrations are critical. Springs excel at both of these functions:

- Damping vibrations: Springs can help dampen the vibrations during travel or operation of a vehicle or machinery. This can prevent excessive shaking or rattling, which can potentially lead to mechanical failures or discomfort for passengers or users.

- Absorbing shocks: They can also help absorb shocks and impacts, reducing the force transferred to the vehicle or machinery and its occupants. This can help protect the structural integrity of the vehicle or machinery, as well as provide a more comfortable and safer experience for users.

By providing these functions, springs can contribute to overall safety and performance by reducing wear and tear on equipment, minimizing the risk of mechanical failure, and improving the overall experience for users.

Force Transmission (Converting energy, Ensuring smooth operation)

Whether it’s in a simple door hinge or a complex mechanical system, understanding how springs manage force transmission is essential for product design. Springs manage force transmission by compressing and expanding in response to external forces. When a force is applied to a spring, it deforms and absorbs the energy and then transmits that energy by pushing back against the force. This allows the spring to transfer the force from one object to another or to store and release energy as needed. In this way, springs help to manage and distribute forces in various mechanical systems.

Alignment and Tension (Precision positioning, Maintaining tension and balance)

Springs are often used to ensure precise alignment and maintain tension in various applications. When your design requires precise positioning and tension management, a spring may be the perfect choice. Springs ensure precise alignment and maintain tension and balance in a system by applying force in a specific direction to bring objects into alignment and maintain tension and balance. When a spring is compressed or stretched, it exerts a force that opposes the compression or stretching, which helps to keep the objects in alignment and maintain tension and balance.

Additionally, springs can be designed with specific properties such as stiffness and load capacity to ensure precise alignment and maintain tension and balance in a system. Overall, springs play a crucial role in mechanical systems by providing the necessary force to keep components aligned and balanced.

Customization of Springs: Tailoring Spring Design for Your Requirements

One of the most remarkable aspects of springs is their ability to be customized for specific load requirements. Springs can be designed to meet the specific load demands of different applications, whether it’s a heavy-duty industrial machine or a delicate medical instrument. Below are some ways customizing springs has helped our customers.

Adapting to Environmental Conditions

We understand that springs often need to function in various environmental conditions, from extreme temperatures to corrosive atmospheres. The variety of materials and simple elegance of springs can make a difference when it comes to long-lasting performance. At Western Spring, we use quality materials to ensure each spring meets the conditions required by our customers.

Size, Shape, and Material Considerations

Characteristics such as size, shape, and material all significantly impact a spring’s performance and can impact how it works in virtually any custom function. When designing a spring, carefully consider these factors to ensure your final product meets the unique requirements of your project.

Space Efficiency and Compact Design When Manufacturing Springs: Utilizing Springs in Compact Spaces

Springs save space and enable more compact product designs. If your design has space limitations, springs might be exactly what you need.

In many cases, springs allow product designers to reduce the need for bulkier, less efficient components. This leads to more streamlined, cost-effective designs. For products that need to be portable and easy to maneuver, springs can be a game-changer, contributing to enhanced portability and maneuverability in different applications.

Different Types of Springs Help with Noise Reduction and Comfort

Springs serve multiple purposes that may be of interest depending on your needs. Below are some functions of springs and ways we work closely with customers to guarantee they’re made exactly your way.

Noise and Vibration Minimization

Noise and vibration can be detrimental to both product performance and user experience. Springs can be employed in various applications to minimize these disruptive factors. If reduced vibration and noise are a concern with your custom project, a standard or custom spring may be a low-cost solution.

Increasing User Comfort and Safety

In consumer products like seating arrangements and ergonomic tools, user comfort and safety are paramount. Stock and custom springs can provide the perfect solution for comfort and safety in your product.

Key Factors to Take into Account as You Design Springs for Your Project

When designing springs for your next project, there are 14 key factors to take into account in order to ensure optimal performance and functionality.

Function and Application Requirements: Determine the specific function the spring will serve in the product. Understand the application requirements, including load capacity, deflection range, and operating conditions.

Material Selection: Choose the appropriate spring material based on mechanical properties, corrosion resistance, and environmental conditions. Consider the material’s cost and availability.

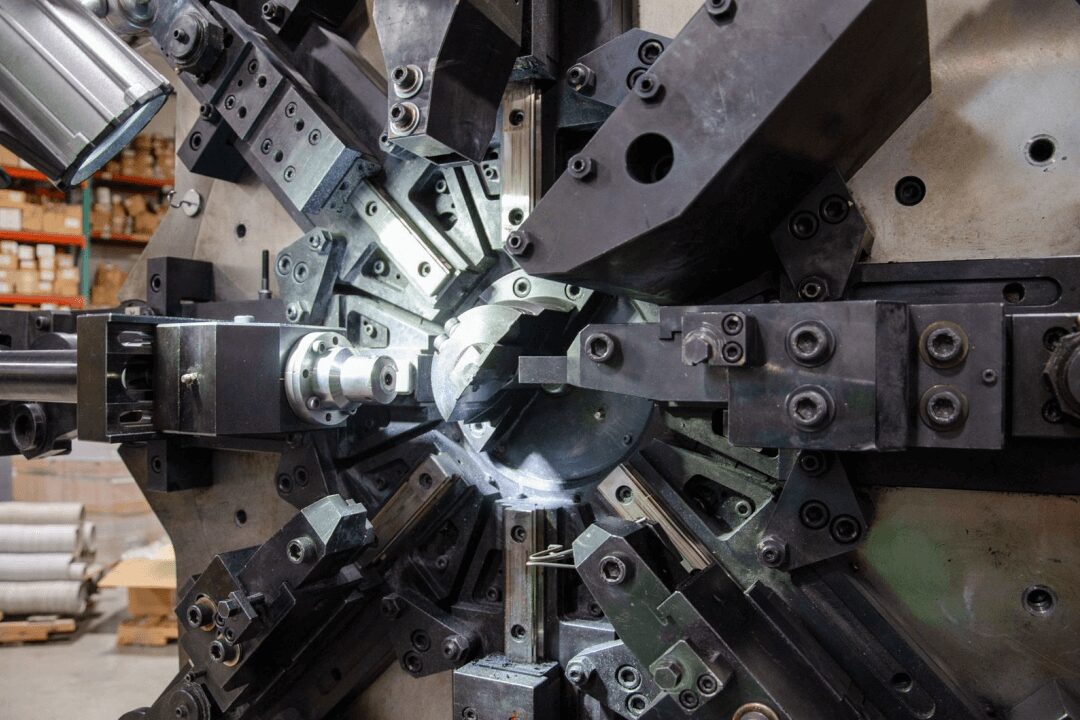

Type of Spring: Select the most suitable type of spring (e.g., coil spring, compression spring, extension spring, torsion spring) based on the application’s needs.

Spring Rate and Stiffness: Calculate the required spring rate or stiffness to ensure the spring is able to provide the necessary force or motion within the specified range.

Size and Geometry: Determine the physical dimensions, such as wire diameter, coil diameter, and free length, based on space constraints and functional requirements.

End Configurations: Choose the appropriate end configurations (e.g., open ends, closed ends, ground ends) that suit the product’s design and assembly.

Deflection and Stress Analysis: Analyze the spring’s deflection and stress under various loads to ensure it operates within safe limits.

Fatigue Life and Durability: Evaluate the expected fatigue life of the spring to ensure it meets the product’s service life requirements.

Environmental Conditions: Account for factors like temperature, humidity, and exposure to chemicals that could affect the spring’s performance or longevity.

Cost and Budget Constraints: Assess the cost of materials, manufacturing processes, and assembly to stay within budget constraints.

Manufacturability: Choose manufacturing processes compatible with the selected spring material and design. Consider factors like heat treatment and surface finishing.

Quality Control and Testing: Plan for quality control measures and testing procedures to ensure the springs meet specified tolerances and performance criteria.

Prototyping and Testing: Develop prototypes to test the spring’s performance in real-world conditions. Create an MVP and make necessary adjustments based on test results.

Life-Cycle Considerations: Think about maintenance and replacement strategies for the spring over the product’s life cycle to ensure long-term functionality.

Designing a spring for a product involves a combination of engineering expertise, material science, and an understanding of the product’s intended use. Collaborating with experienced engineers and spring manufacturers is important to ensure the design meets all necessary requirements and specifications.

When You Design a Custom Spring or Wire Form With Western Spring

We are dedicated to helping you achieve the best possible functionality for your products through our spring design services. Your success is our success, and we look forward to collaborating with you to bring your innovative ideas to life. When you work with Western Spring, you get:

- Expert guidance in selecting the most suitable spring type and material.

- Thorough analysis to ensure the spring meets all performance and safety requirements.

- A commitment to quality and precision in every aspect of spring design and manufacturing.

- A partner who understands the importance of cost-effectiveness and on-time delivery.

Before you get started on your next design, learn more about our design assistance and how we help our customers. When you choose Western Spring Manufacturing for your spring design needs, you experience the difference that expertise and commitment make in ensuring the success of your products.