Western Spring Manufacturing

Spring and Wire Form Design Assistance

1

Spring and Wire Form Design Assistance

Overall Usage Requirements

There are several specific considerations for designing effective springs and wire forms. These considerations include material properties, loading and stress management, usage tolerance, spring rate, safety considerations, and space constraints.

Your finished product may also need to meet applicable industry standards such as ASTM (American Society for Testing and Materials) or ISO (international organization for standardization), as well as any governmental restrictions.

ISO 9001:2015

Spring Manufacturers Institue

2

Spring and Wire Form Design Assistance

Spring or Wire Form Type

Based on your specific usage requirements, the primary step in designing a spring or wire form is to select the appropriate type for the particular application.

Springs come in many shapes and forms, each with specific advantages and disadvantages based on their intended purpose.

We understand that proper manufacturing of your essential spring components provide superior longevity in a variety of applications across different industries.

We specialize in the design, development, and manufacture of custom clock springs for a wide range of applications.

Western Spring Manufacturers specializes in providing high-performance custom springs that are engineered to meet the most demanding industrial requirements.

We understand that extension springs come in various end types and sizes, and we’re here to help you design the perfect solution for your unique application.

Flat springs are an essential component in many mechanical and industrial applications, and our team at Western Springs is proud to be one of the leading flat spring manufacturers in the industry.

As a trusted provider of medical coiling services, we understand the importance of precision engineering and reliability in medical coil manufacturing.

At Western Spring Manufacturing we are committed to providing our clients with the best possible solutions for their torsion spring needs.

3

Spring and Wire Form Design Assistance

Material Selection

The material selection process is a crucial step of spring or wire form design. The material chosen needs to be strong enough to withstand the required force and application while also being cost-effective and unobtrusive for the end product.

Different types of materials may also require specific production techniques and processes.

Raw Material Options

- Music wire

- Stainless Steel -302/304, 17-7

- Inconel

- Hastelloy

- Titianium

- MP35N

- Elgiloy

- Monel

- Hard Drawn

- Hard Drawn Galvanized

- Oil Tempered

- Chrome Silicon

- Chrome Silicon Valve Grade

- Phosphor Bronze

- Beryllium Copper

- Nichrome-Resistance wire

4

Spring and Wire Form Design Assistance

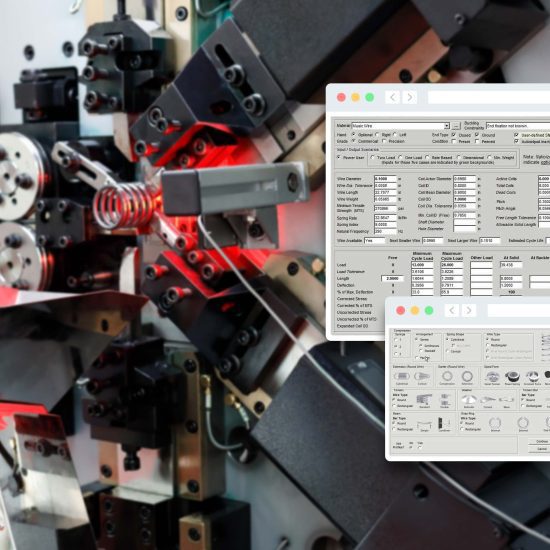

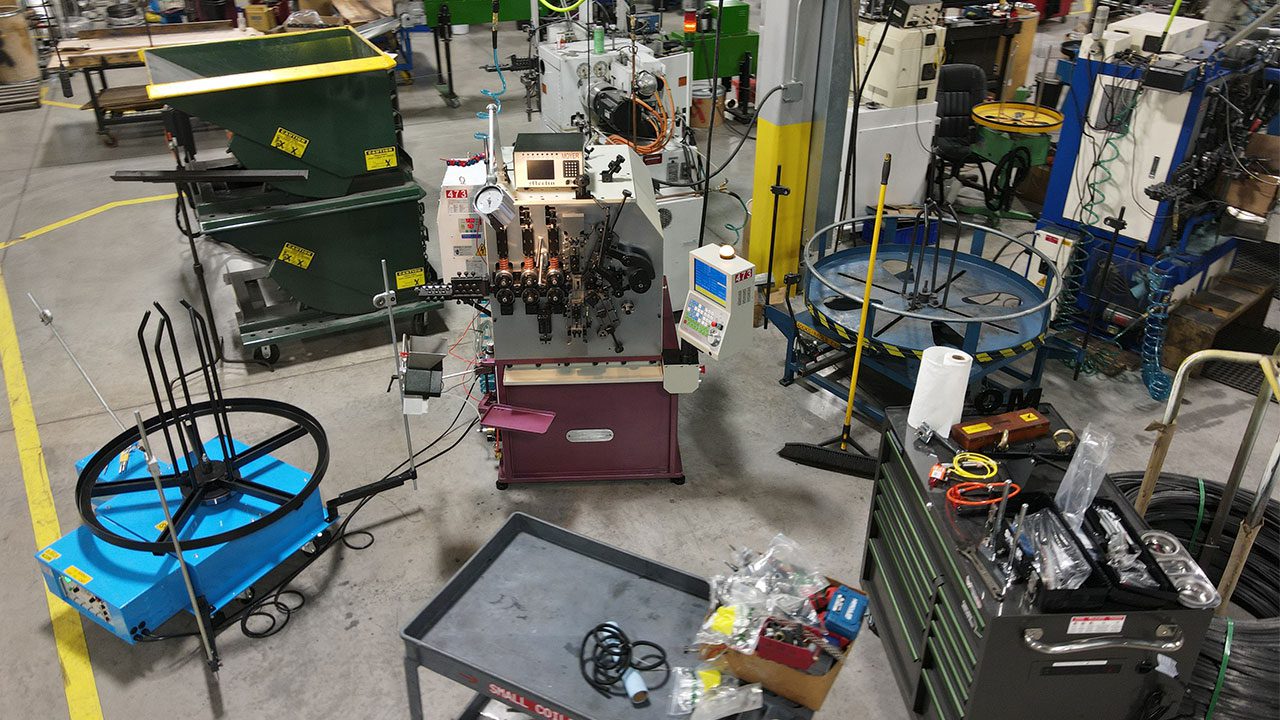

Production Method

Once the type and material have been selected, the production method must be determined. This step requires considering production speed and accuracy, cost, and labor requirements.

Depending on the products requirements, the production process may include cold forming, compression molding, coiling, or wire forming.

Additional Processes

- Grinding

- Pre-setting

- Load testing

- Shot peening

- Vibratory finishing

- Heat treating

Finishing Options

- Electro-Plating: Zinc Chromate

- Pre-Galvanized wire

- Electropolishing of SS

- Powder coating: Any color available

- Electro-Deposition Coating (E-Coating)

- Thermal Dip Paint:Black only

5

Spring and Wire Form Design Assistance

Final Packaging and Delivery

Safe and successful delivery of manufactured springs requires a great deal of attention and care. By taking the appropriate packaging, shipping, and storage considerations into account, the process can be streamlined and the springs can be safely delivered to their final destination.

As springs are delicate parts, they need to be packaged in a way that prevents damage during transport.

Packaging Options

- Shipping Containers

- Cardboard or Corrugated Cardboard Boxes

- Plastic Boxes / Containers

- Bagged / Zipper Storage

- Foam or Bubble Wrap Protection

Shipping Options

- Ground Shipping Services

- Air Freight Services

- Parcel Services

- Local In-Person Pick Up

Connect with our Technical Sales Team

to discuss your project.

Our design assistance will help you produce a cost effective and long lasting solution for your spring and wire form needs.