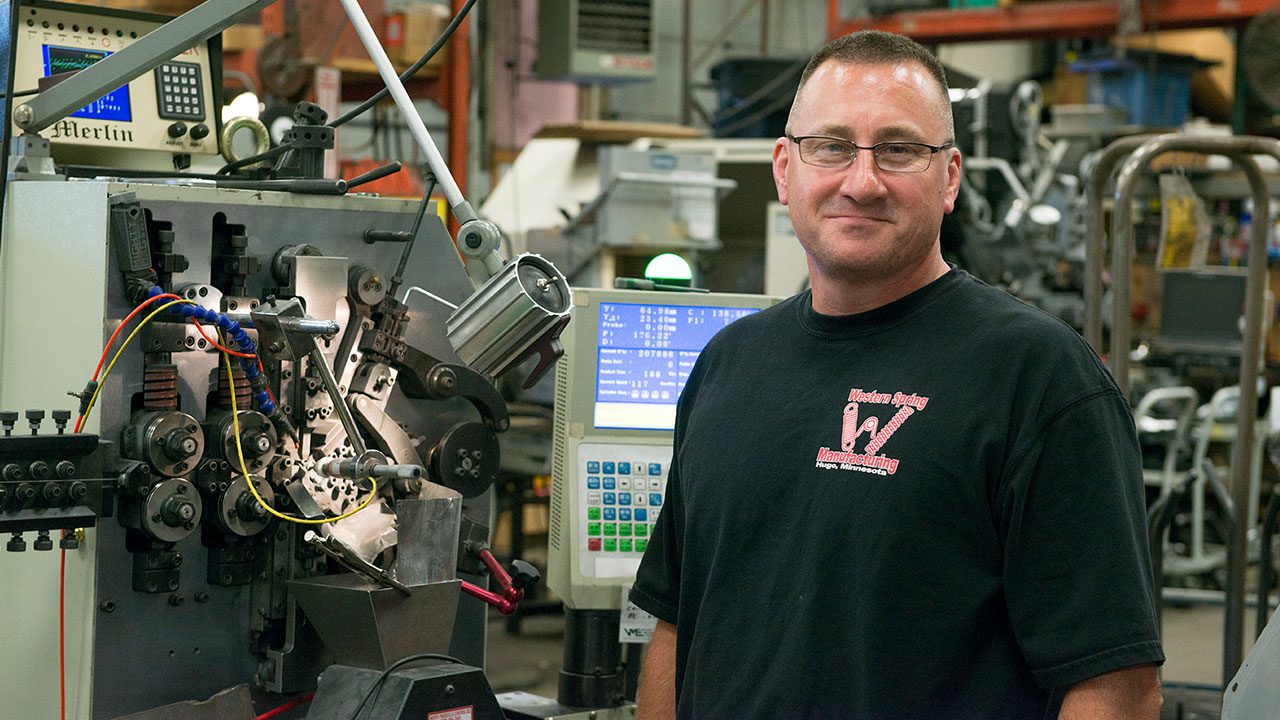

Western Spring Manufacturing

Die Spring Manufacturing

Die Spring Quality

Quality Die Spring Applications

- Superior Design:

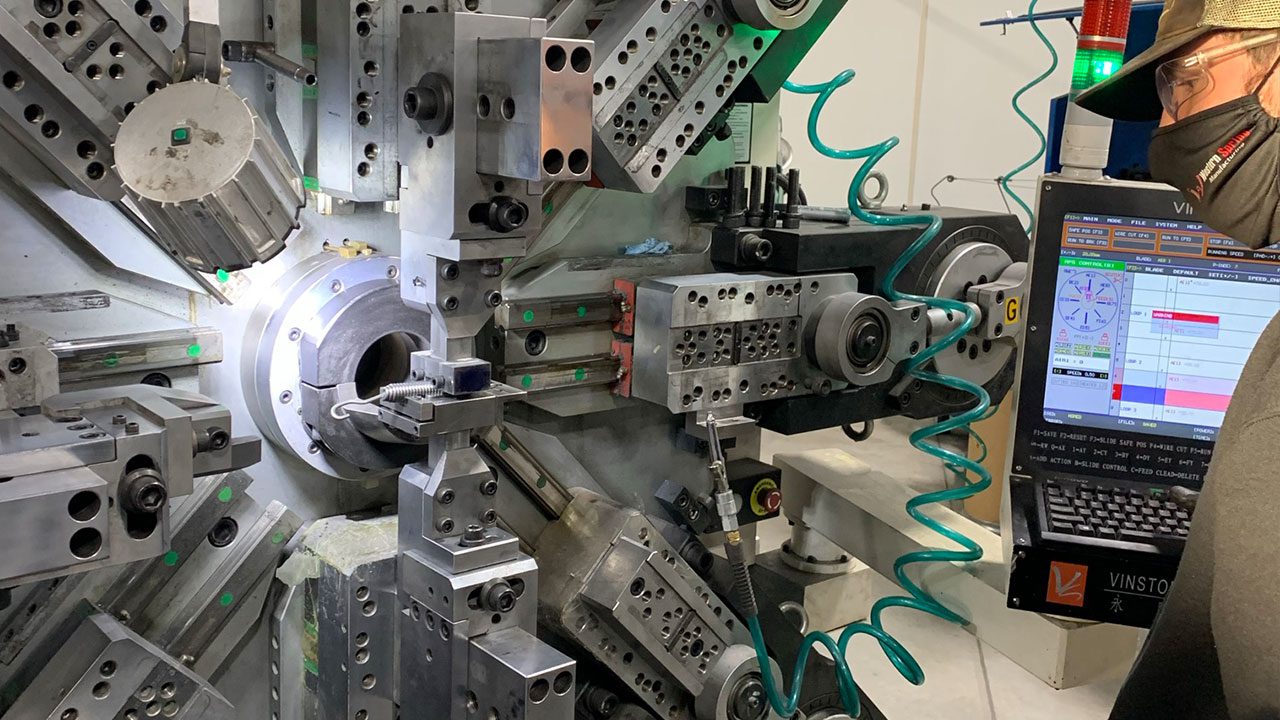

Design must be perfect to keep your die springs operating under heavy loads without spring failure. The manufacturing process begins with design and our engineers are the best and helping you find the mechanical spring design you need. Our expertise along with your design result in a synergy that ensures that your die springs are ideal. - Quality Materials:

You require quality springs and that requires materials that meet or exceed specifications. Great coils come from great wire and we test every metric to assure you that your springs meet mechanical requirements. - Precision Manufacturing:

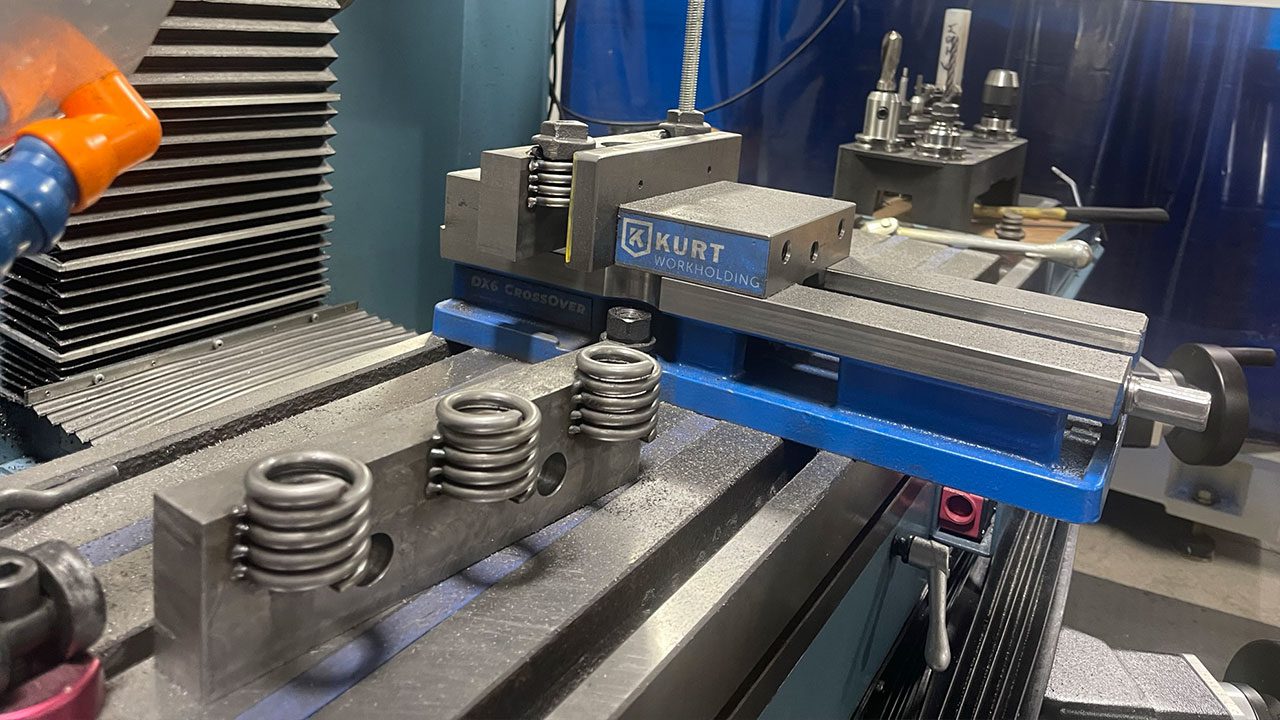

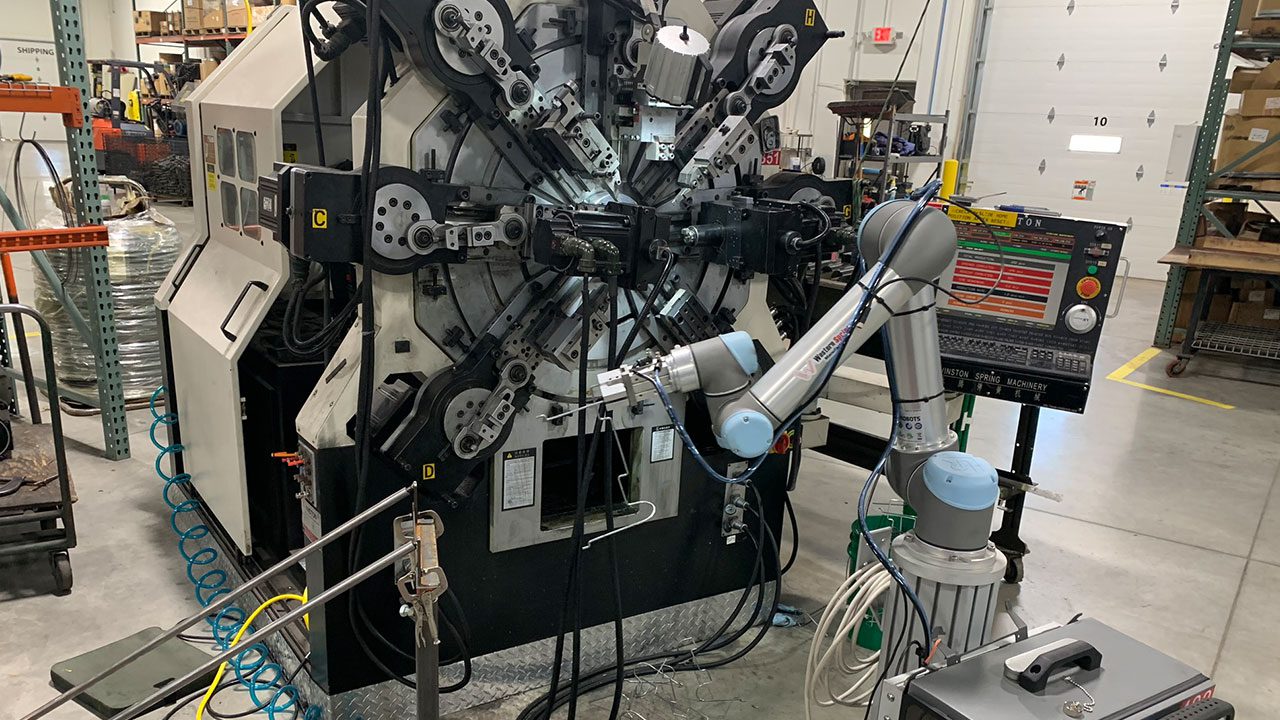

Precision is the name of the game in manufacturing and our state-of-the-art facility and experienced engineers are critical in the process of ensuring that your die springs are manufactured exactly as you specify.

Compression Spring Customization

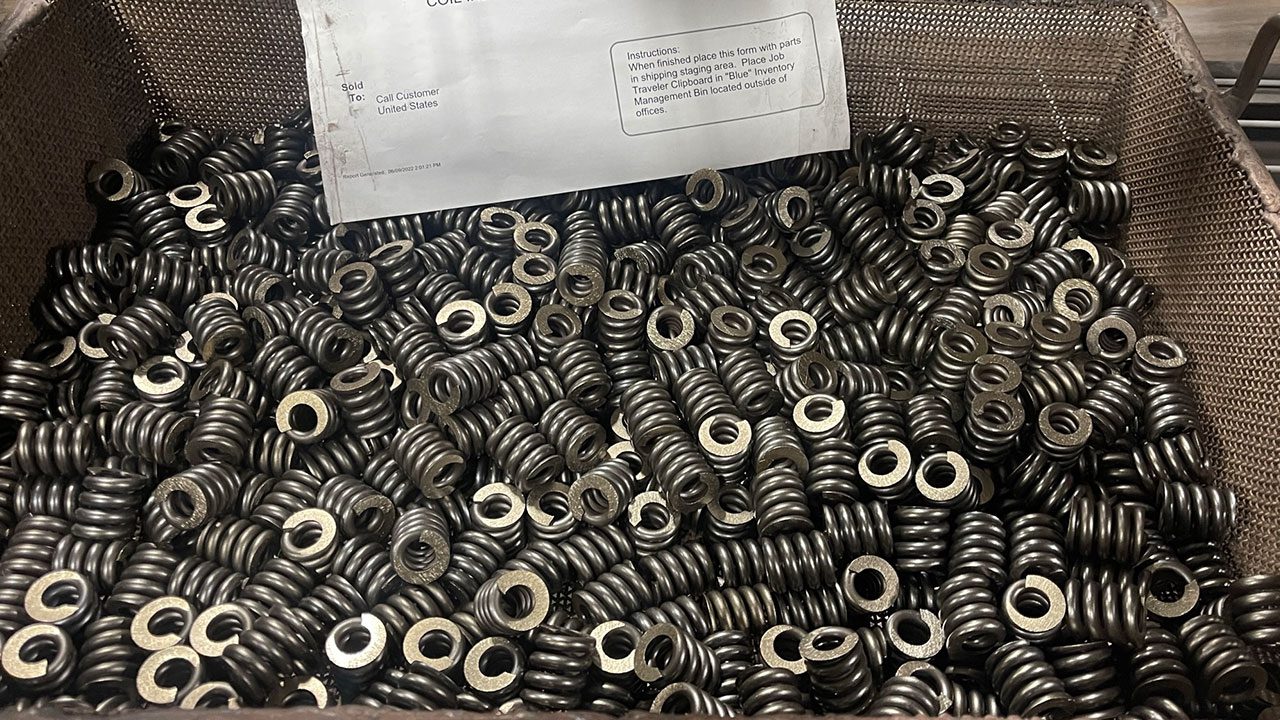

Custom Die Spring Coil Manufacture: Crafting All Types of Die Springs

Die Spring design is not always one-size-fits-all. We at Western Spring pride ourselves on having the best engineers and top-notch customer service. No other manufacturer will offer you better service and when you need custom springs made, our team is clutch. We work hard so you can be sure your custom heavy duty metal compression springs manufactured with us, are perfect.

Die Spring Testing

Using Die Spring Testing Precise Enough to Deliver Top Results

In the world of heavy machinery and industrial applications, precision is paramount. At Western Spring Manufacturing, our die springs undergo rigorous testing to guarantee impeccable performance.

- Load Testing:

This test involves subjecting the die spring to different loads to verify that it can compress and return to its original position without deformation or failure. It ensures that the spring can handle the expected loads in the application. - Deflection Testing:

This test measures the spring’s deflection under a specified load. It helps determine the spring’s behavior when subjected to a particular force and ensures it meets the design requirements. - Stress and Strain Testing:

This involves evaluating the spring’s response to applied stress. It helps determine the spring’s elastic and plastic deformation behavior and ensures it can handle the expected working conditions. - Material Analysis:

Testing the material properties of the spring, including tensile strength, yield strength, and composition, ensures it meets the specified standards for the application.

Spring Specifications

Raw Material Options

- Music wire

- Stainless Steel -302/304, 17-7

- Inconel

- Hastelloy

- Titianium

- MP35N

- Elgiloy

- Monel

- Hard Drawn

- Hard Drawn Galvanized

- Oil Tempered

- Chrome Silicon

- Chrome Silicon Valve Grade

- Phosphor Bronze

- Beryllium Copper

- Nichrome-Resistance wire

Additional Processes

- Grinding

- Pre-setting

- Load testing

- Shot peening

- Vibratory finishing

- Heat treating

Finishing Options

- Electro-Plating: Zinc Chromate

- Pre-Galvanized wire

- Electropolishing of SS

- Powder coating: Any color available

- Electro-Deposition Coating (E-Coating)

- Thermal Dip Paint: Black only

Our Certifications

ISO 9001:2015

Western Spring holds the complete ISO 9001:2015 Certification for the manufacturing and distribution of springs and wire forms. Certification Number CERT-0103669

Spring Manufacturers Institute

Western Spring is a proud member of the Spring Manufacturers Institute (SMI) and completes ongoing training and educational events to improve our manufacturing processes.

Frequently Asked Die Spring Questions (FAQs)

What are die springs?

What are the benefits of using die springs?

How do I select the right die spring for my application?

What materials are die springs made of?

What are the color codes used for die springs?

Can die springs be customized as per my specific requirements?

How long do die springs last?

Can I use die springs for non-industrial applications?

Can I order die springs in small quantities?

Don’t take our word for it

Phenomenal Customer Service!!! Zach Hawley, THE Tech Sales Manager, has been the only spring manufacturer capable of providing a turnkey winding and grinding solution for our extremely high tolerance… Read More

Phenomenal Customer Service!!! Zach Hawley, THE Tech Sales Manager, has been the only spring manufacturer capable of providing a turnkey winding and grinding solution for our extremely high tolerance requirements. Most manufacturers have No Quoted my RFQs, but Western Spring has stood strong.

Ryan A.

Yorktown, VA

Very impressed with the team at Western Spring Manufacturing. They are quick to respond to requests and have been great to work with.

We needed a spring for an old hydraulic valve and we couldn’t find anything from any hydraulic shop. I called Western Spring and talked to Alex and he said bring it In and we will see what we can… Read More

We needed a spring for an old hydraulic valve and we couldn’t find anything from any hydraulic shop. I called Western Spring and talked to Alex and he said bring it In and we will see what we can do. We had a production line down so this was a hot part. Got in and Alex had pulled some comparable springs and we found one that worked. If it wasn’t for Alex and Western Spring we would still be line down. Thanks for all the help and the great customer service, you guys run a great shop.

Adam H.

Lino Lakes, MN

The office staff at Western Spring Manufacturing are awesome to work with. They easily help me with our spring needs and pointed us in the right direction to address our needs!!

Have Questions?

Connect with our spring design team to discuss your project.

Additional Spring and Wire Form Products