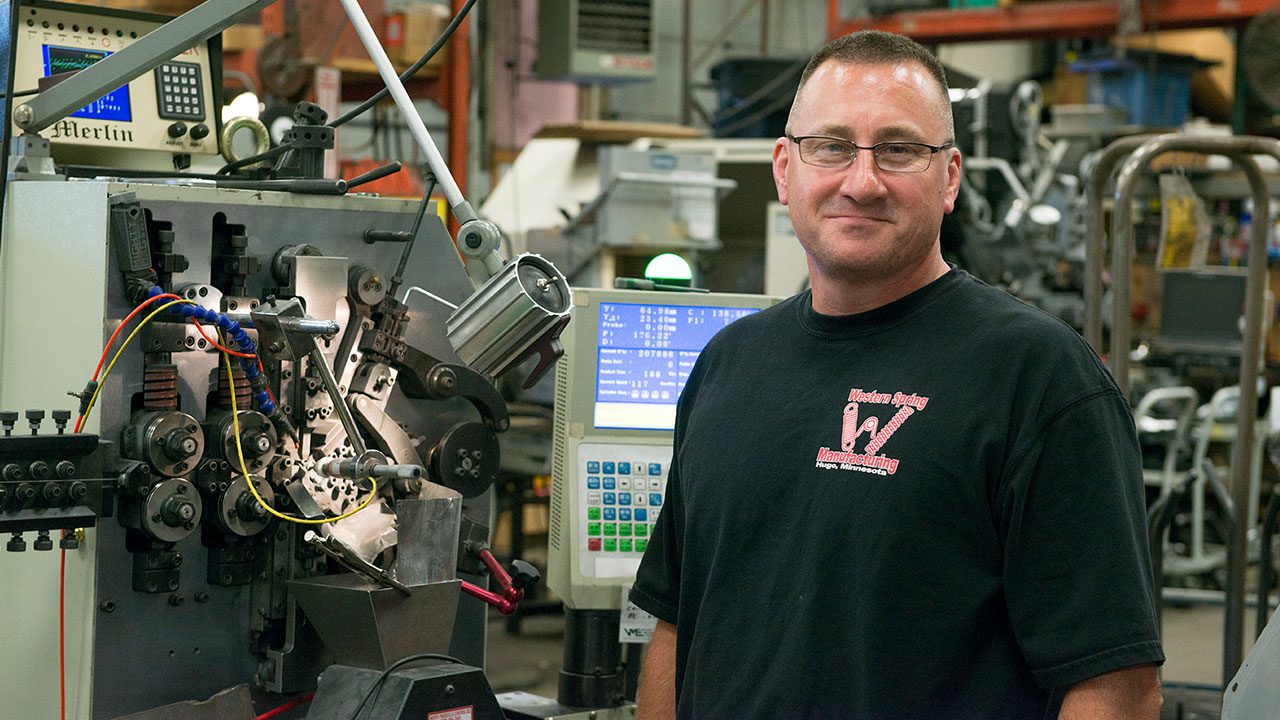

Western Spring Manufacturing

Medical Coil and Wire Manufacturing

Medical Coil Quality

Unparalleled Quality in Medical Coil Manufacturing

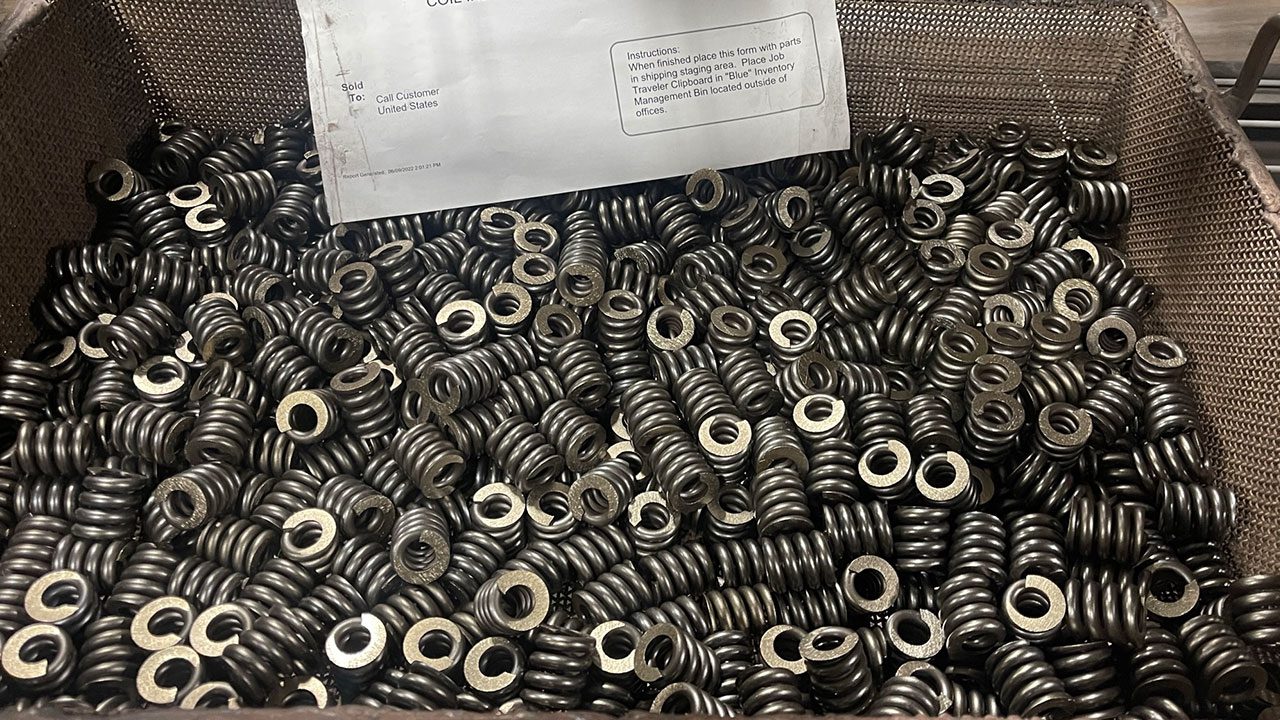

Our manufacturing process adheres to complete ISO standards, ensuring that each coil is produced to the highest industry benchmarks. From prototype to final product, we leave no room for compromise. We understand the demanding nature of medical applications. That’s why we go the extra mile to deliver coils that not only meet but exceed expectations.

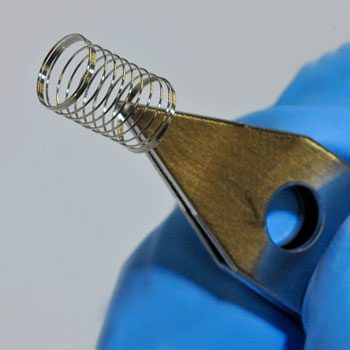

Our high-performance coils are engineered to thrive in even the most challenging environments, providing superior performance when it matters most. We source only the finest materials, meticulously chosen for their purity, reliability, and biocompatibility.

- Superior Design:

We employ cutting-edge design techniques to engineer medical coils that meet or exceed industry standards. - Quality Materials:

We source only the finest materials, meticulously chosen for their purity, reliability, and biocompatibility. - Precision Manufacturing:

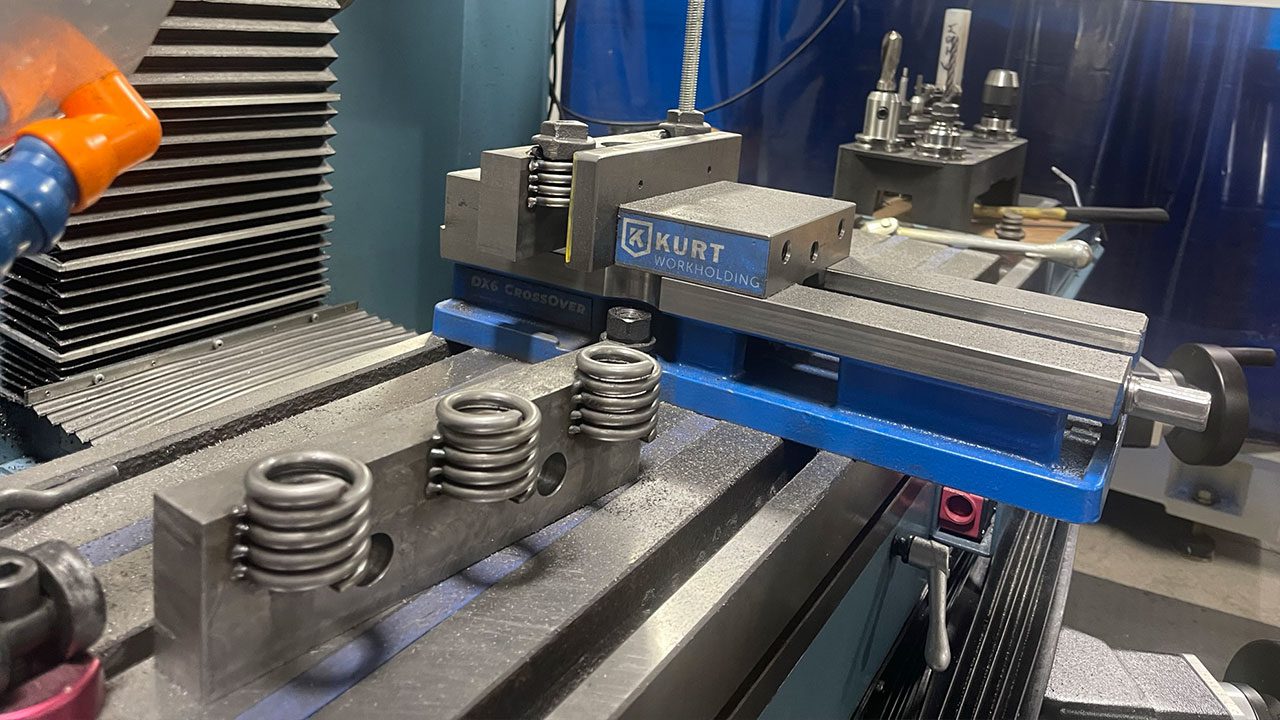

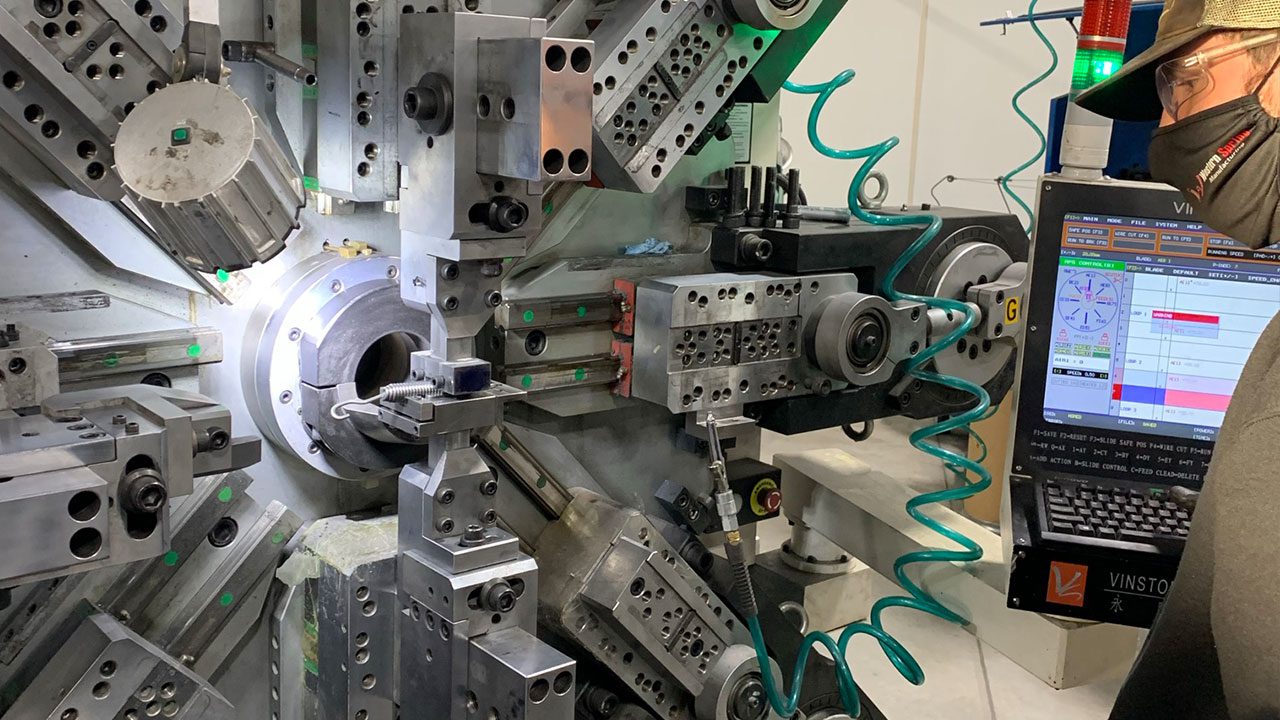

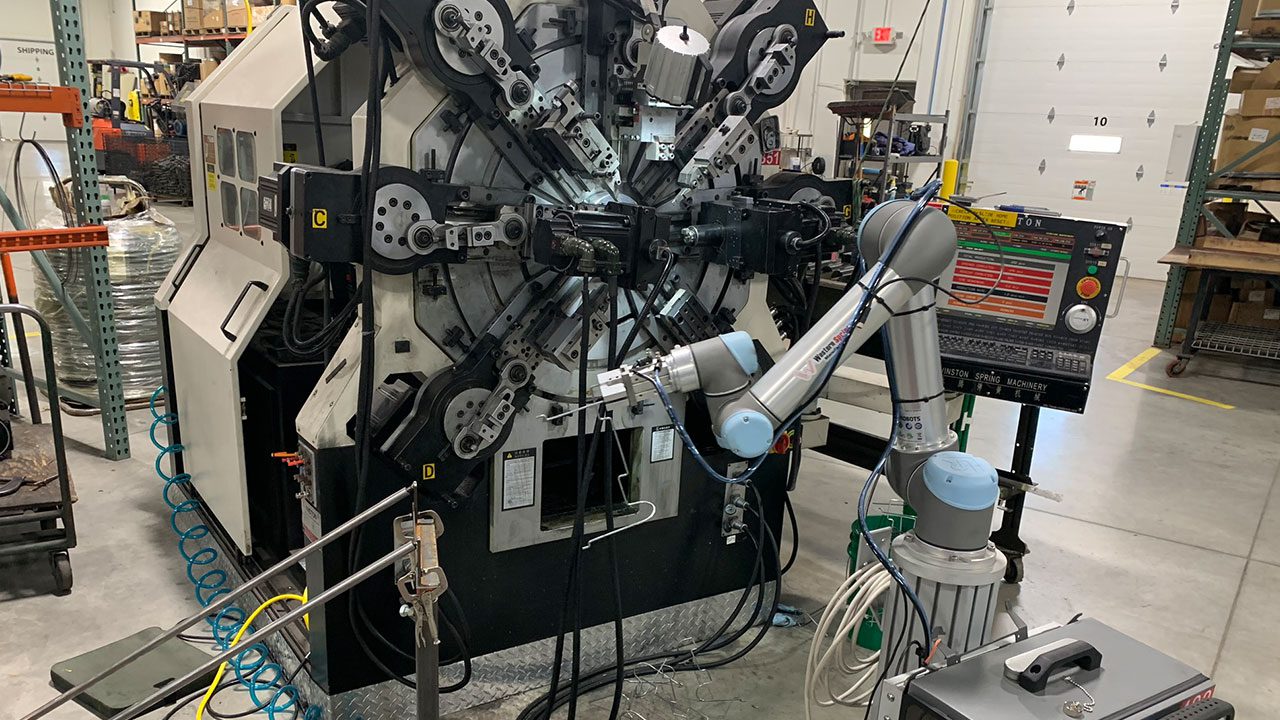

Our state-of-the-art facilities are dedicated to engineering excellence, ensuring every product adheres to the most stringent industry standards.

Medical Coil Customization

Customized Medical Coil Solutions Tailored to Your Needs

In the world of minimally invasive procedures, precision is paramount. Our coils are engineered to provide the utmost accuracy, allowing for seamless integration into even the most complex medical devices. Our coils equate to confidence in meeting ISO requirements and in turn, helping people live their healthiest lives.

We understand that every customer has unique needs, so we offer personalized service to ensure that your coils meet your specific requirements. Our team will work with you from the initial consultation to the final product to ensure that your coils are tailor-made to your exact specifications.

Our commitment to quality and customer satisfaction is unmatched, and we strive to provide exceptional service at every step of the way. Whether you need a single custom coil or a large order, we have the expertise and experience to deliver the results you need. Feel free to click below to request a quote or contact us for design assistance.

Medical Coil Testing

Our commitment to unparalleled Medical Spring quality is unwavering

- Rigorous Testing:

Every wire and coil undergoes exhaustive testing protocols, guaranteeing flawless performance and unwavering safety. - Temperature and Performance Testing:

We subject our wires to rigorous temperature extremes and performance benchmarks to ensure they maintain accuracy and reliability in demanding medical applications. - Dimensional Accuracy Testing:

We employ advanced measurement techniques to confirm dimensional accuracy down to the micrometer level. - Material Integrity Analysis:

Our thorough material analysis ensures that our wires meet the highest standards of purity and biocompatibility, essential for medical device safety. - Load and Stress Testing:

We simulate real-world conditions to assess the strength and resilience of our wires, guaranteeing they can withstand the most demanding medical environments.

Our commitment to quality and customer satisfaction is unmatched, and we strive to provide exceptional service at every step of the way. Whether you need a single custom coil or a large order, we have the expertise and experience to deliver the results you need.

Spring Specifications

Raw Material Options

- Music wire

- Stainless Steel -302/304, 17-7

- Inconel

- Hastelloy

- Titianium

- MP35N

- Elgiloy

- Monel

- Hard Drawn

- Hard Drawn Galvanized

- Oil Tempered

- Chrome Silicon

- Chrome Silicon Valve Grade

- Phosphor Bronze

- Beryllium Copper

- Nichrome-Resistance wire

Additional Processes

- Grinding

- Pre-setting

- Load testing

- Shot peening

- Vibratory finishing

- Heat treating

Finishing Options

- Electro-Plating: Zinc Chromate

- Pre-Galvanized wire

- Electropolishing of SS

- Powder coating: Any color available

- Electro-Deposition Coating (E-Coating)

- Thermal Dip Paint: Black only

Our Certifications

ISO 9001:2015

Western Spring holds the complete ISO 9001:2015 Certification for the manufacturing and distribution of springs and wire forms. Certification Number CERT-0103669

Spring Manufacturers Institute

Western Spring is a proud member of the Spring Manufacturers Institute (SMI) and completes ongoing training and educational events to improve our manufacturing processes.

Frequently Asked Medical Coil Questions (FAQs)

What are medical coils, and how are they used in the healthcare industry?

What materials do you use to manufacture medical coils, and why are these materials chosen?

What is the typical size range and tolerance level for medical coils you manufacture?

Can you provide examples of specific medical devices or applications where your coils are commonly used?

Do you offer custom design and manufacturing services for specialized medical coil requirements?

Does Western Spring Manufacturing offer prototyping services?

Is Western Spring Manufacturing able to handle both small and large-scale production runs?

How can I get in touch with Western Spring Manufacturing for more information or to discuss a project?

Don’t take our word for it

Phenomenal Customer Service!!! Zach Hawley, THE Tech Sales Manager, has been the only spring manufacturer capable of providing a turnkey winding and grinding solution for our extremely high tolerance… Read More

Phenomenal Customer Service!!! Zach Hawley, THE Tech Sales Manager, has been the only spring manufacturer capable of providing a turnkey winding and grinding solution for our extremely high tolerance requirements. Most manufacturers have No Quoted my RFQs, but Western Spring has stood strong.

Ryan A.

Yorktown, VA

Very impressed with the team at Western Spring Manufacturing. They are quick to respond to requests and have been great to work with.

We needed a spring for an old hydraulic valve and we couldn’t find anything from any hydraulic shop. I called Western Spring and talked to Alex and he said bring it In and we will see what we can… Read More

We needed a spring for an old hydraulic valve and we couldn’t find anything from any hydraulic shop. I called Western Spring and talked to Alex and he said bring it In and we will see what we can do. We had a production line down so this was a hot part. Got in and Alex had pulled some comparable springs and we found one that worked. If it wasn’t for Alex and Western Spring we would still be line down. Thanks for all the help and the great customer service, you guys run a great shop.

Adam H.

Lino Lakes, MN

The office staff at Western Spring Manufacturing are awesome to work with. They easily help me with our spring needs and pointed us in the right direction to address our needs!!

Have Questions?

Connect with our spring design team to discuss your project.

Additional Spring and Wire Form Products