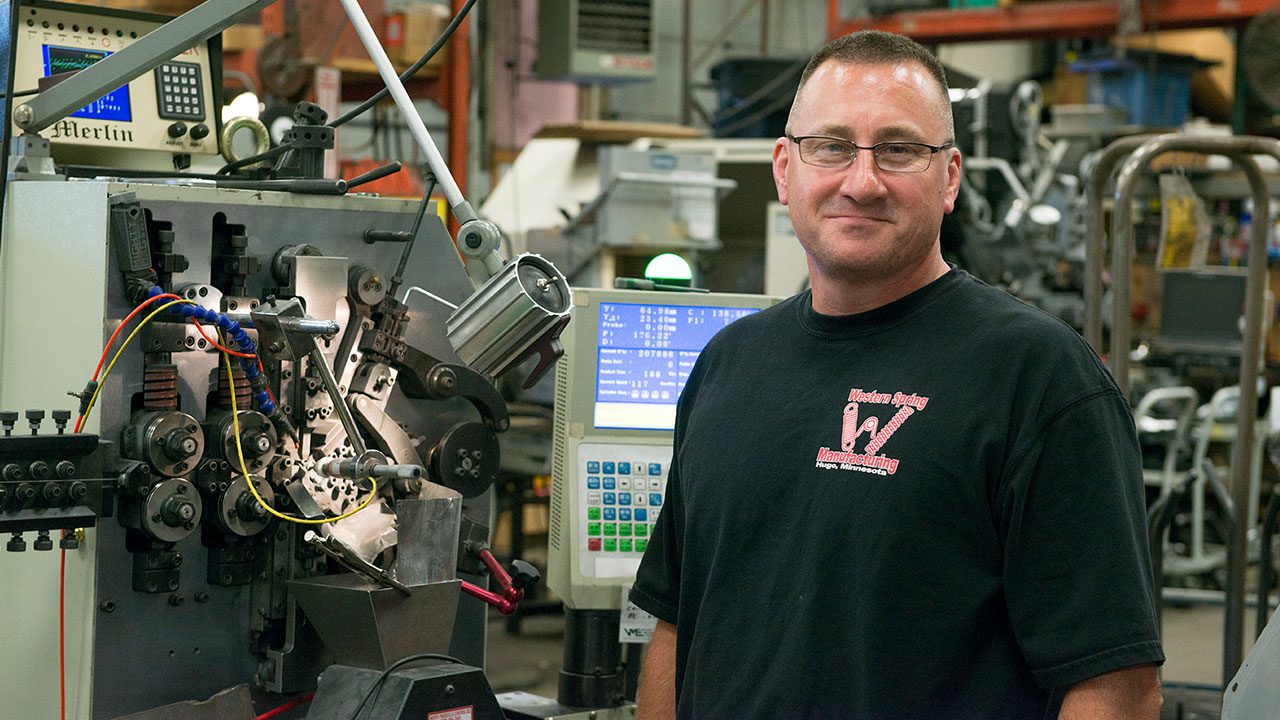

Western Spring Manufacturing

Wire Form Manufacturing

Wire Form Quality

Unmatched Quality and Precision in the Wire Form Manufacturing Process

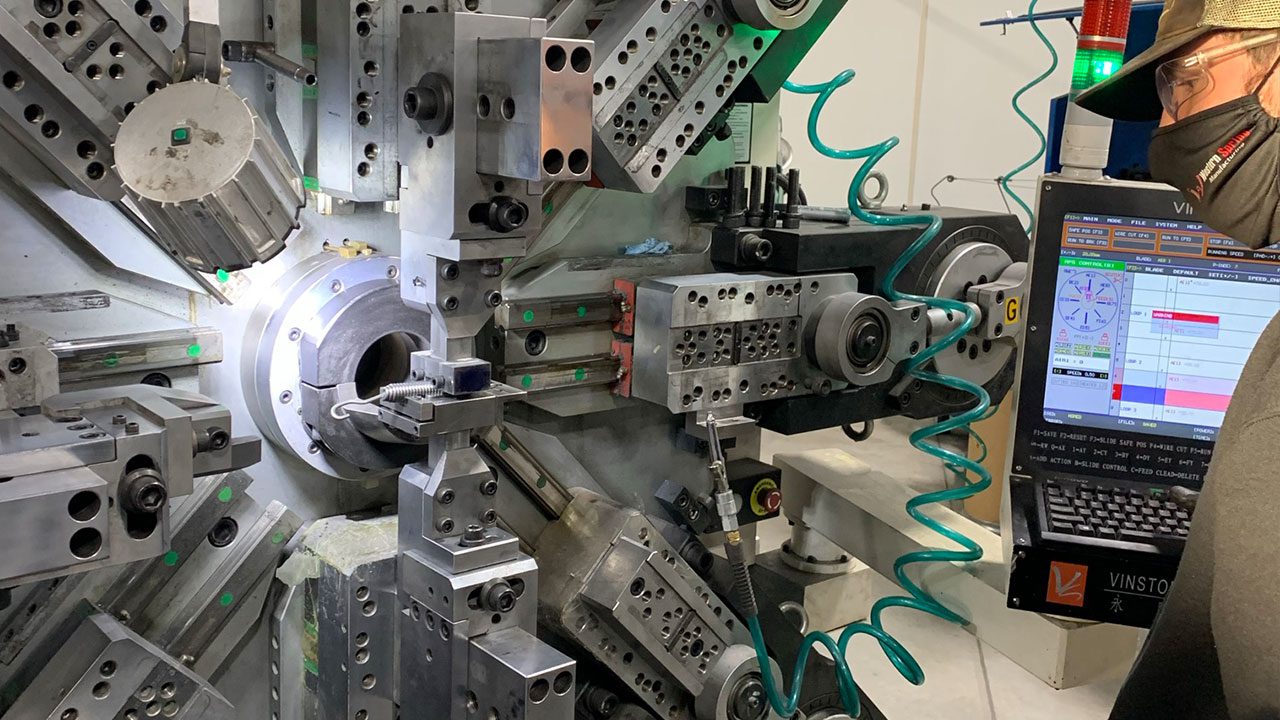

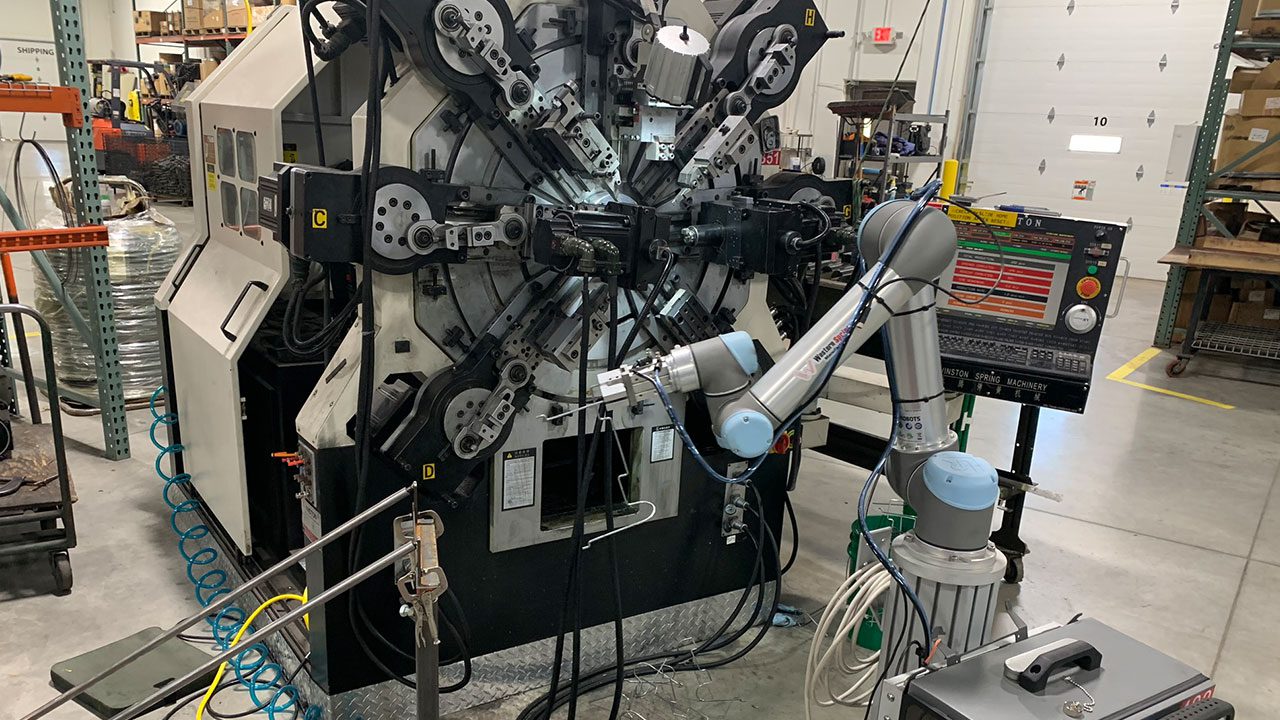

When it comes to wire form manufacturing, there is no room for compromise. Our dedicated team of skilled engineers and technicians employs state-of-the-art equipment and advanced techniques to fabricate custom wire form products of exceptional quality and precision. From straightforward designs to intricate custom creations, we have the proficiency and resources to bring your visions to life.

You don’t compromise on the quality of your products and we don’t compromise on the quality of the wire forms you require.

- Superior Design:

We employ cutting-edge design techniques to engineer wire forms that meet or exceed industry standards. - Quality Materials:

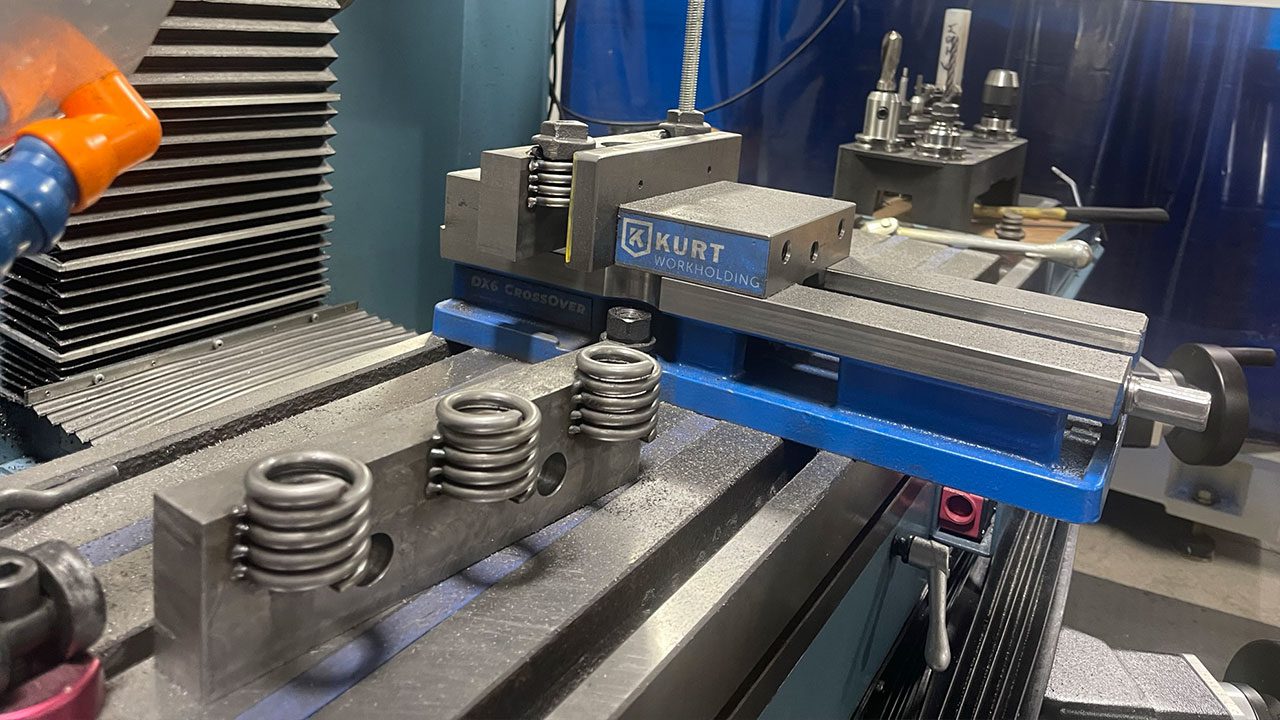

We source only the highest-quality materials, chosen for their durability, reliability, and functionality. - Precision Manufacturing:

Our state-of-the-art facilities are dedicated to precision engineering, ensuring that each wire form adheres to the strictest industry standards.

Wire Form Customization

Tailored Wire Form Products for Your Unique Requirements

At Western Spring, we recognize that off-the-shelf solutions don’t always cut it. That’s why we specialize in providing custom wire form solutions to meet your specific needs. We understand that each project demands a unique approach, and our engineering team will work closely with you to deliver the ideal wire form to suit your needs.

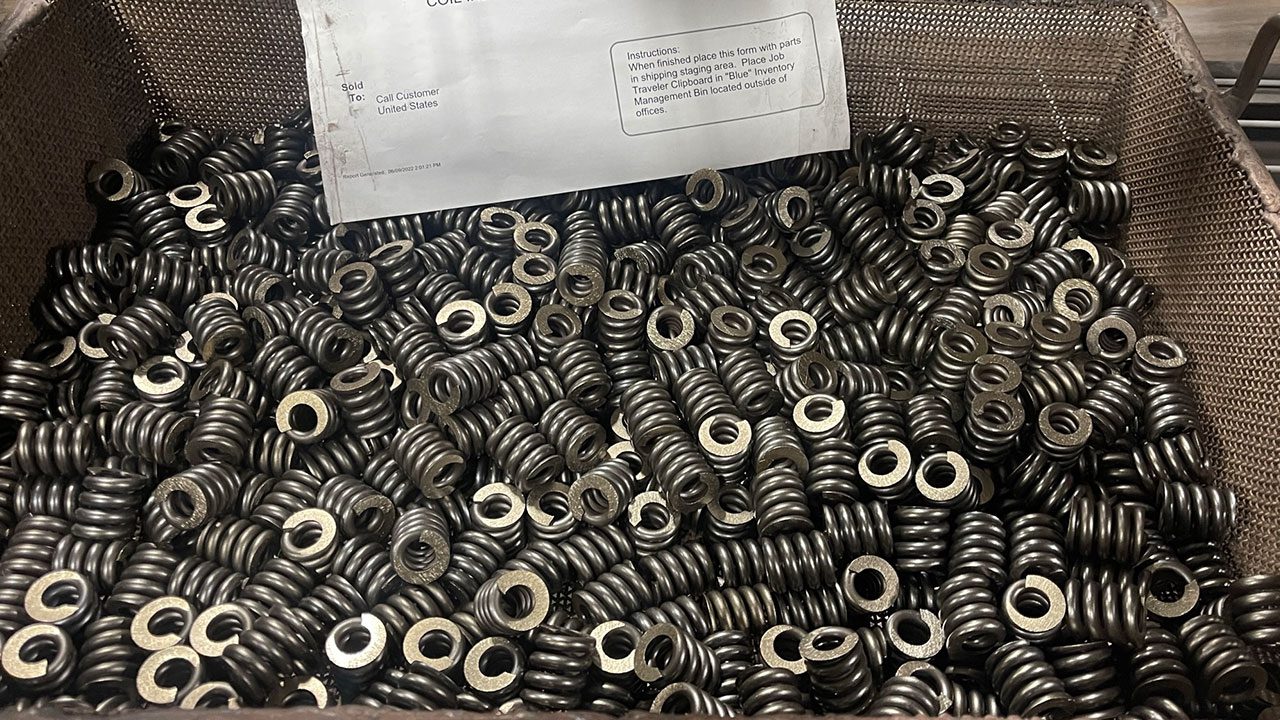

From conceptualizing wire form designs to prototyping, full-scale production and custom packaging, our team is your dedicated partner throughout the entire process. Whether you require a small batch of specialized bent wire forms or a large-scale production run, our extensive expertise ensures cost-effective solutions that align precisely with your requirements.

Wire Form Testing

Engineered Excellence in Custom Wire Bending Technologies

- Material Testing:

We conduct comprehensive material analysis to ensure the integrity and performance of the wire forms. - Dimensional Accuracy:

We employ advanced measurement techniques to confirm dimensional accuracy, guaranteeing precise fit and function. - Operational Testing:

Our wire forms undergo thorough operational tests to ensure they function correctly in real-world applications. - Quality Assurance:

Our quality control checks are second to none, ensuring that every wire form we produce meets the highest standards of excellence.

Spring Specifications

Raw Material Options

- Music wire

- Stainless Steel -302/304, 17-7

- Inconel

- Hastelloy

- Titanium

- MP35N

- Elgiloy

- Monel

- Hard Drawn

- Hard Drawn Galvanized

- Oil Tempered

- Chrome Silicon

- Chrome Silicon Valve Grade

- Phosphor Bronze

- Beryllium Copper

- Nichrome-Resistance wire

Additional Processes

- Grinding

- Pre-setting

- Load testing

- Shot peening

- Vibratory finishing

- Heat treating

Finishing Options

- Electro-Plating: Zinc Chromate

- Pre-Galvanized wire

- Electropolishing of SS

- Powder coating: Any color available

- Electro-Deposition Coating (E-Coating)

- Thermal Dip Paint: Black only

Our Certifications

ISO 9001:2015

Western Spring holds the complete ISO 9001:2015 Certification for the manufacturing and distribution of springs and wire forms. Certification Number CERT-0103669

Spring Manufacturers Institute

Western Spring is a proud member of the Spring Manufacturers Institute (SMI) and completes ongoing training and educational events to improve our manufacturing processes.

Frequently Asked Wire Form Questions (FAQs)

What sets Western Spring Manufacturing apart from other wire form manufacturers?

Can Western Spring Manufacturing create custom wire forms to meet specific requirements?

What industries does Western Spring Manufacturing serve?

How can I request a quote for a custom wire form project?

What is the typical lead time for custom wire form production?

Does Western Spring Manufacturing offer prototyping services?

What quality assurance measures does Western Spring Manufacturing have in place?

Is Western Spring Manufacturing able to handle both small and large-scale production runs?

How can I get in touch with Western Spring Manufacturing for more information or to discuss a project?

Don’t take our word for it

Phenomenal Customer Service!!! Zach Hawley, THE Tech Sales Manager, has been the only spring manufacturer capable of providing a turnkey winding and grinding solution for our extremely high tolerance… Read More

Phenomenal Customer Service!!! Zach Hawley, THE Tech Sales Manager, has been the only spring manufacturer capable of providing a turnkey winding and grinding solution for our extremely high tolerance requirements. Most manufacturers have No Quoted my RFQs, but Western Spring has stood strong.

Ryan A.

Yorktown, VA

Very impressed with the team at Western Spring Manufacturing. They are quick to respond to requests and have been great to work with.

We needed a spring for an old hydraulic valve and we couldn’t find anything from any hydraulic shop. I called Western Spring and talked to Alex and he said bring it In and we will see what we can… Read More

We needed a spring for an old hydraulic valve and we couldn’t find anything from any hydraulic shop. I called Western Spring and talked to Alex and he said bring it In and we will see what we can do. We had a production line down so this was a hot part. Got in and Alex had pulled some comparable springs and we found one that worked. If it wasn’t for Alex and Western Spring we would still be line down. Thanks for all the help and the great customer service, you guys run a great shop.

Adam H.

Lino Lakes, MN

The office staff at Western Spring Manufacturing are awesome to work with. They easily help me with our spring needs and pointed us in the right direction to address our needs!!

Have Questions?

Connect with our spring design team to discuss your project.

Additional Spring and Wire Form Products