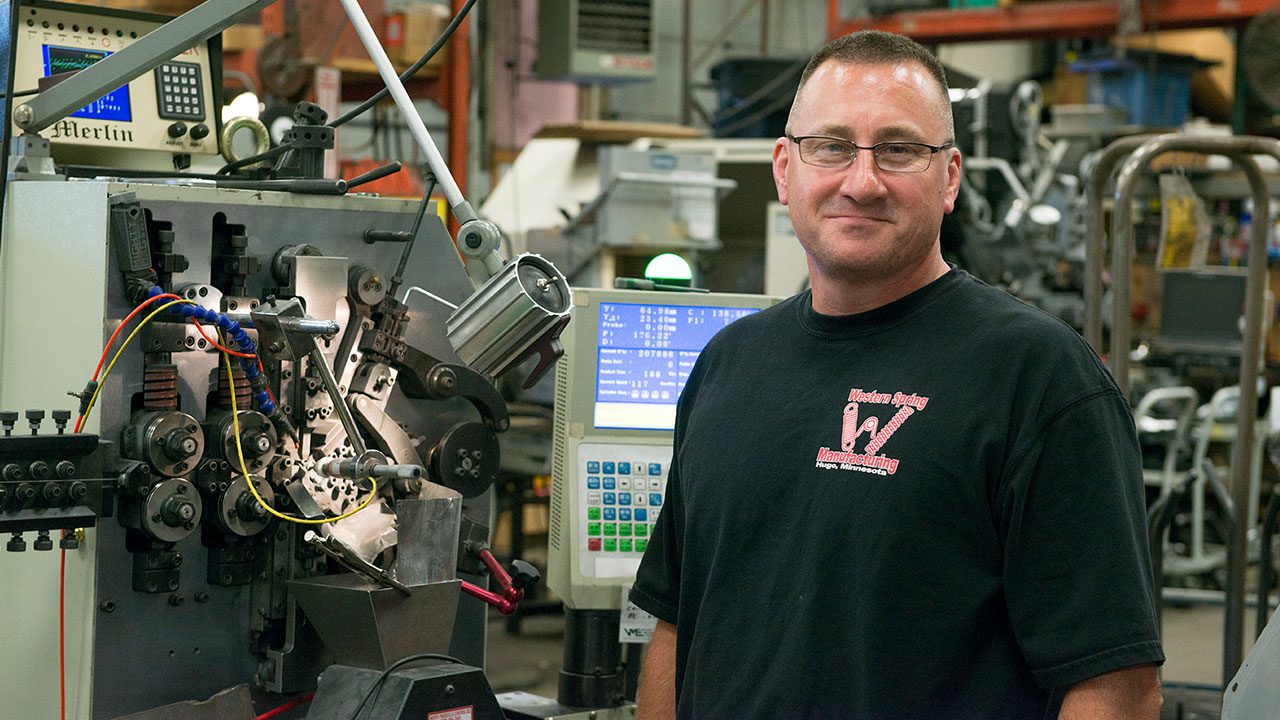

Western Spring Manufacturing

Extension Spring Manufacturing

Extension Spring Quality

Highest Quality Stock Extension Spring and Custom Extension Spring Manufacturing

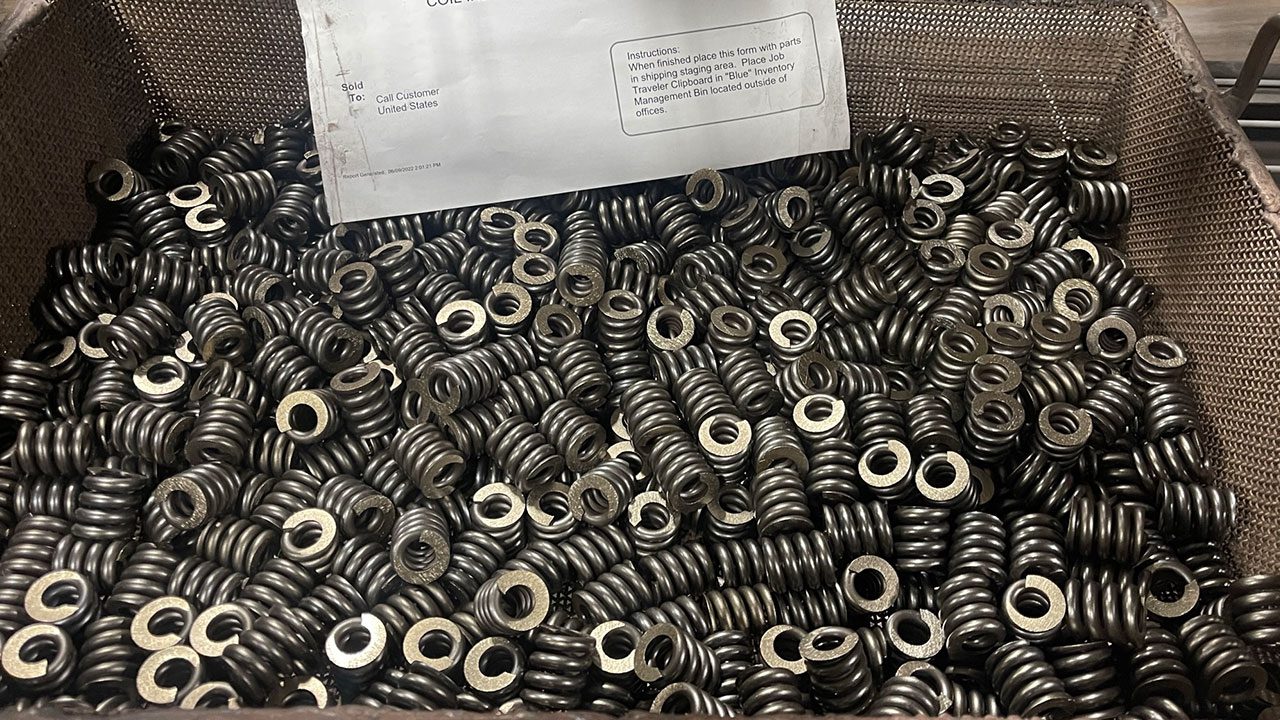

Your customers demand the highest quality springs for maximum load capacity and at Western Spring we have the springs you need. Our commitment to the highest quality spring for your application starts with the spring stock and doesn’t end until we pack and ship the last coil to complete your order.

As a family-owned company, we understand that quality is at the core of our ability continue having success in this industry. That’s why we only we work so hard to craft a spring that exactly meets your every measurement and parameter. Quality is in our DNA and that means that springs made at Western Spring are the finest around.

- Superior Design:

With decades of experience, our engineers can help you design your ideal custom extension spring. Not everyone has springs in stock for you and that is where we come in with our proven design track record. - Quality Materials:

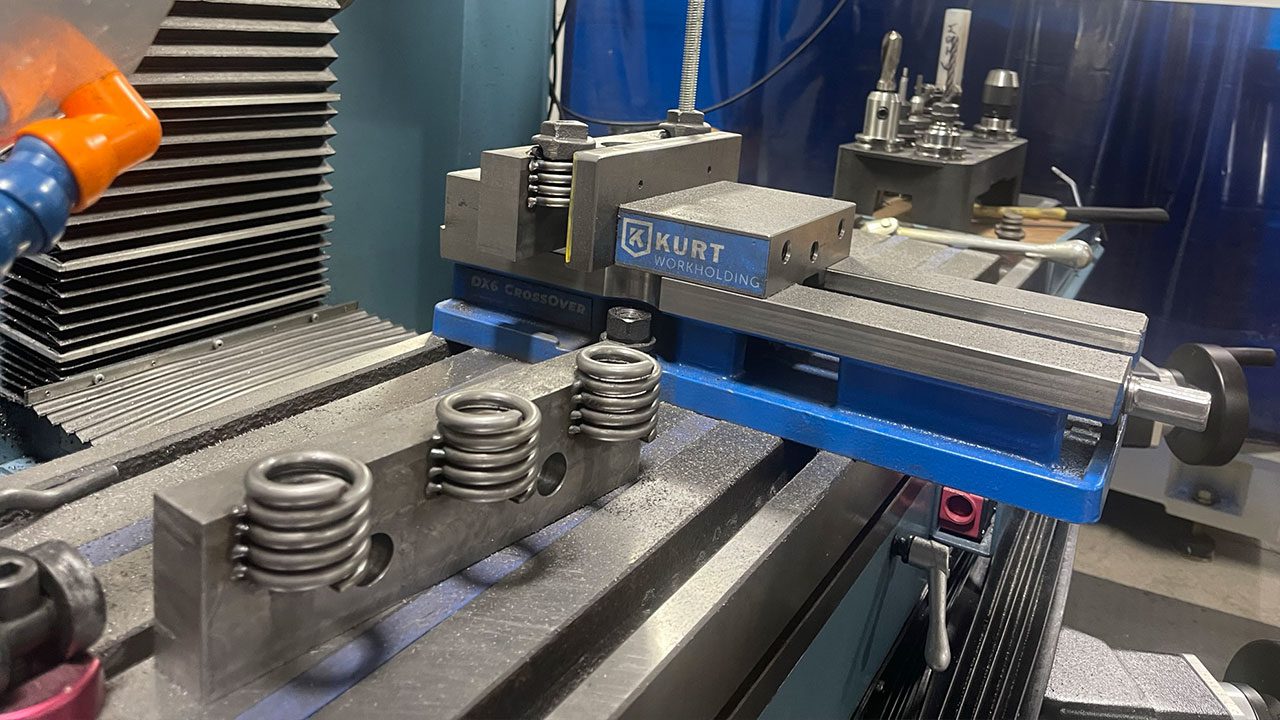

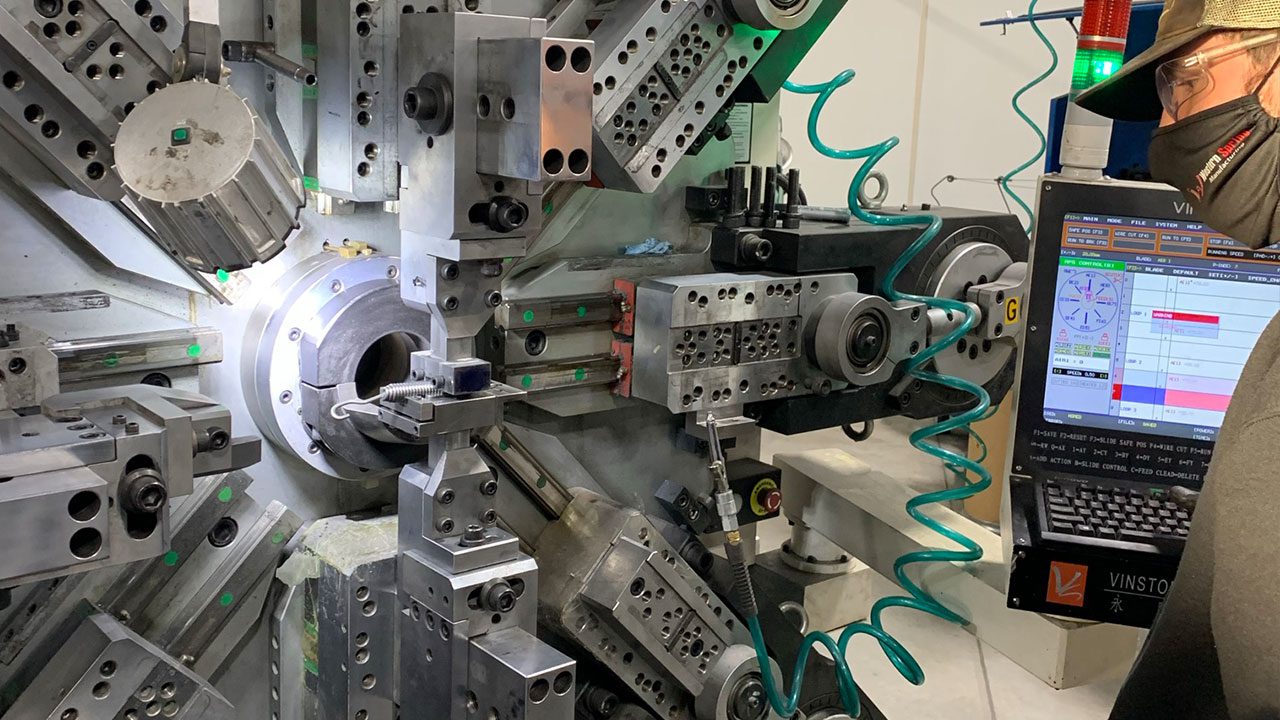

The best springs require the best materials and we inspect every lot to ensure that we offer the materials to make a spring that meets your standards. You require the best quality extension springs and we use quality materials to make that happen. - Precision Manufacturing:

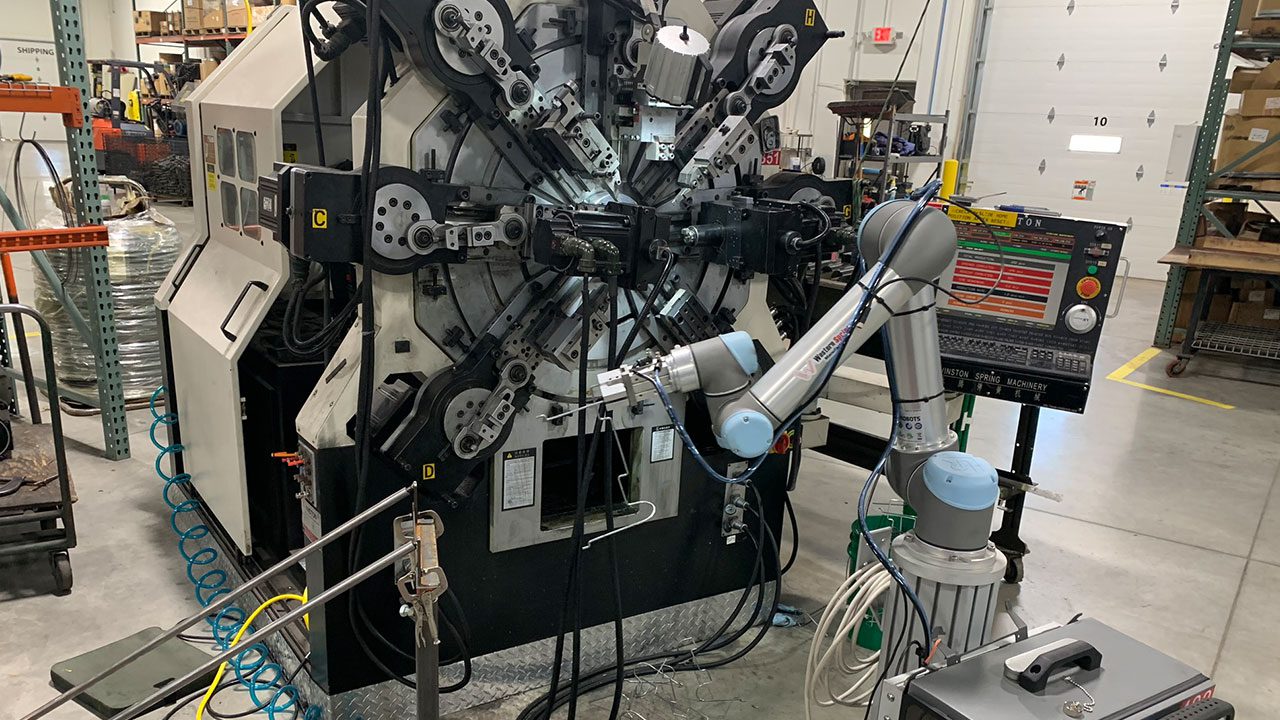

Our state-of-the-art machinery and testing equipment ensure that our quality control processes and procedures are above industry standards. Precise control means precision manufacturing to achieve the load requirements that you need in your order, whether you need custom or stock springs.

Extension Spring Customization

Custom Extension Coil Configurations Made To Your Measurements

Your springs are more than just wire. They are more than a product. They are your unique offering to the people who count on you. you can count on us at Western Spring to deliver your custom springs your way. If you need help at any point, we are here for you from prototype to product and ensure fast delivery of your custom springs. Contact us today to get your custom order started.

Extension Spring Testing

We Rigorously Test and Measure Your Extension Springs to Meet Every Parameter You Require

- Material Testing:

We monitor every lot of wire material that is submitted for testing and prototyping to ensure the highest quality product. - Dimensional Accuracy:

This involves measuring critical dimensions of the extension spring, such as wire diameter, outer diameter, length, and the number of active coils. This ensures that the spring conforms to your specified design requirements. - Load Testing:

This test involves subjecting the extension spring to various loads to verify that it can extend and retract without any deformation or failure. The load should be applied gradually to prevent sudden overloading. - Elasticity and Stress Testing:

This test evaluates how well the spring returns to its original shape after being stretched. It measures factors like modulus of elasticity and yield strength to ensure the spring can handle the expected loads. - Fatigue Testing:

Extension springs are often subjected to repeated cycles of loading and unloading. Fatigue testing simulates these conditions to ensure the spring can withstand the anticipated number of cycles without failure. - Load Testing:

This involves applying a load to the spring and measuring the corresponding deflection. This helps characterize the spring’s behavior under different loads. - Visual Inspection:

A visual examination of the spring is crucial to identify any surface defects, such as cracks, pitting, or other anomalies.

Spring Specifications

Raw Material Options

- Music wire

- Stainless Steel -302/304, 17-7

- Inconel

- Hastelloy

- Titianium

- MP35N

- Elgiloy

- Monel

- Hard Drawn

- Hard Drawn Galvanized

- Oil Tempered

- Chrome Silicon

- Chrome Silicon Valve Grade

- Phosphor Bronze

- Beryllium Copper

- Nichrome-Resistance wire

Additional Processes

- Grinding

- Pre-setting

- Load testing

- Shot peening

- Vibratory finishing

- Heat treating

Finishing Options

- Electro-Plating: Zinc Chromate

- Pre-Galvanized wire

- Electropolishing of SS

- Powder coating: Any color available

- Electro-Deposition Coating (E-Coating)

- Thermal Dip Paint: Black only

Our Certifications

ISO 9001:2015

Western Spring holds the complete ISO 9001:2015 Certification for the manufacturing and distribution of springs and wire forms. Certification Number CERT-0103669

Spring Manufacturers Institute

Western Spring is a proud member of the Spring Manufacturers Institute (SMI) and completes ongoing training and educational events to improve our manufacturing processes.

Frequently Asked Extension Spring Questions (FAQs)

What materials are commonly used for extension springs?

What are the best practices for end treatment and finishing of extension springs?

What quality control measures should be implemented during manufacturing?

Don’t take our word for it

Phenomenal Customer Service!!! Zach Hawley, THE Tech Sales Manager, has been the only spring manufacturer capable of providing a turnkey winding and grinding solution for our extremely high tolerance… Read More

Phenomenal Customer Service!!! Zach Hawley, THE Tech Sales Manager, has been the only spring manufacturer capable of providing a turnkey winding and grinding solution for our extremely high tolerance requirements. Most manufacturers have No Quoted my RFQs, but Western Spring has stood strong.

Ryan A.

Yorktown, VA

Very impressed with the team at Western Spring Manufacturing. They are quick to respond to requests and have been great to work with.

We needed a spring for an old hydraulic valve and we couldn’t find anything from any hydraulic shop. I called Western Spring and talked to Alex and he said bring it In and we will see what we can… Read More

We needed a spring for an old hydraulic valve and we couldn’t find anything from any hydraulic shop. I called Western Spring and talked to Alex and he said bring it In and we will see what we can do. We had a production line down so this was a hot part. Got in and Alex had pulled some comparable springs and we found one that worked. If it wasn’t for Alex and Western Spring we would still be line down. Thanks for all the help and the great customer service, you guys run a great shop.

Adam H.

Lino Lakes, MN

The office staff at Western Spring Manufacturing are awesome to work with. They easily help me with our spring needs and pointed us in the right direction to address our needs!!

Have Questions?

Connect with our spring design team to discuss your project.

Additional Spring and Wire Form Products