To design the perfect spring for your application, you have to have as much information related to usage as possible. This includes knowing why springs might fail.

Knowing and identifying possible reasons for failure allows you to design the most robust spring possible.

Let’s talk about spring failure.

Common Reasons for Manufactured Spring Failures: A Technical Breakdown

Failure can be predictable and understanding common failures can lead to better spring production.

Here are 7 common reasons for spring failure:

1. Non-Calculated Spring Stress

Non-calculated spring stress is a primary contributor to failures. It occurs when the applied load exceeds the spring’s designed capacity, leading to stress levels beyond the material’s yield strength.

The calculation of spring stress involves considering factors like wire diameter, coil diameter, and the number of active coils. When these parameters are not accurately calculated or exceed recommended limits, it results in overstressing the spring, causing deformation or even fracture.

If you have a prototype or spring set that needs testing, contact us here.

2. Incorrect Spring Material Choice

Selecting the appropriate material for a spring is critical to its performance and longevity. Springs are commonly made from materials like high-carbon steel, stainless steel, or alloys.

Incorrect material choice, such as using a material with insufficient tensile strength or inadequate resistance to corrosion, can lead to premature failure. Factors like fatigue life, spring rate, and corrosion resistance must be meticulously considered during the material selection process.

3. Incorrect Finish Selection

The finish of a spring plays a crucial role in its corrosion resistance and overall durability. Choosing an incorrect finish, whether it’s inadequate coating thickness or an unsuitable material, can expose the spring to environmental elements leading to corrosion.

The selection of finishes should align with the working environment and potential corrosive agents. For example, zinc plating may be suitable for certain applications, while others may require epoxy or polymer coatings.

4. Undefined Cycle Life

The cycle life of a spring refers to the number of cycles it can undergo before experiencing failure. Failure can occur due to fatigue, where repeated loading and unloading cause microstructural changes in the material.

When the cycle life is undefined or not accurately determined during the design phase, the spring may fail prematurely, affecting the overall reliability of the system it supports.

5. Undefined Working Temperature

Springs operating in extreme temperatures must be designed to withstand thermal stresses. Failure can result from material embrittlement, loss of temper, or thermal fatigue.

If the working temperature range is not precisely defined during the design phase, it may lead to unexpected thermal stresses and degradation of the spring material.

Understanding the coefficient of thermal expansion and selecting materials accordingly is crucial to preventing temperature-related failures.

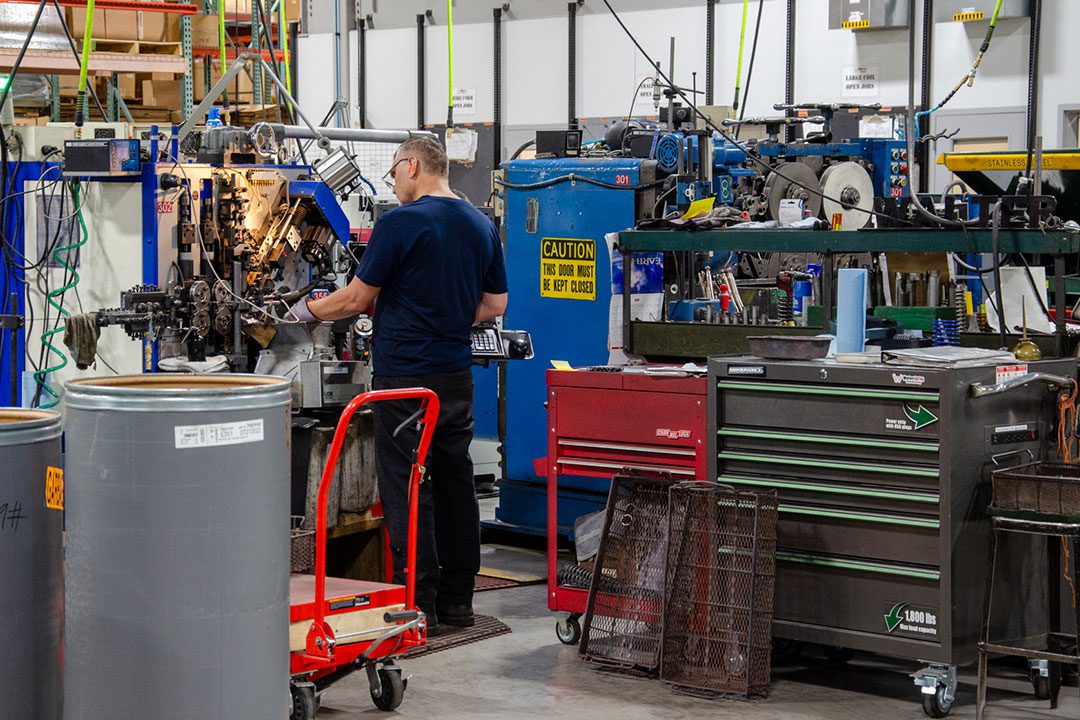

6. Inferior Manufacturing Processes

The manufacturing processes used to create springs significantly impact their performance.

Inferior processes, such as inadequate heat treatment, imprecise coiling, or improper stress relief, can introduce internal defects or alter material properties. These defects weaken the spring and contribute to failure.

We employ high-quality manufacturing processes, including precision coiling, shot peening, and controlled heat treatment, is essential for ensuring the integrity of the spring.

7. Undefined Interaction with Mating Components

Springs often function within a system, interacting with other components. An undefined interaction with mating components can lead to issues such as misalignment, uneven loading, or excessive vibration.

This lack of clarity in the design phase regarding how the spring interacts with other elements can result in unintended stresses and fatigue, ultimately leading to failure. Proper consideration of the overall system dynamics is crucial for preventing failures related to undefined interactions.

Manufacturing Processes and Spring Reliability

The manufacturing process significantly influences the reliability of springs, and various factors can impact their performance. Here are several ways in which the manufacturing process can affect the reliability of springs:

1. Material Selection:

The choice of materials, including their composition and quality, plays a crucial role in determining the mechanical properties and overall reliability of the spring.

At Western Spring, we use only the highest quality materials and would be glad to consult with you about which material is best for your application.

2. Heat Treatment:

Proper heat treatment processes are essential to enhance the material’s mechanical properties, such as hardness and yield strength, ensuring the spring can withstand operational stresses.

3. Surface Finish and Coating:

The surface finish of a spring, including any coatings applied, can affect its resistance to corrosion and wear, directly impacting its longevity and reliability.

We have only the highest quality finishes and coatings available and also would be happy to help with design assistance.

4. Precision in Manufacturing:

Accurate manufacturing processes, including precision in coiling and forming, are vital to maintaining the desired dimensions and characteristics of the spring. Deviations can lead to performance issues.

At Western Spring, quality is job one. Every piece we run is meticulously inspected and tested to meet specifications. We go above and beyond to ensure only the highest quality.

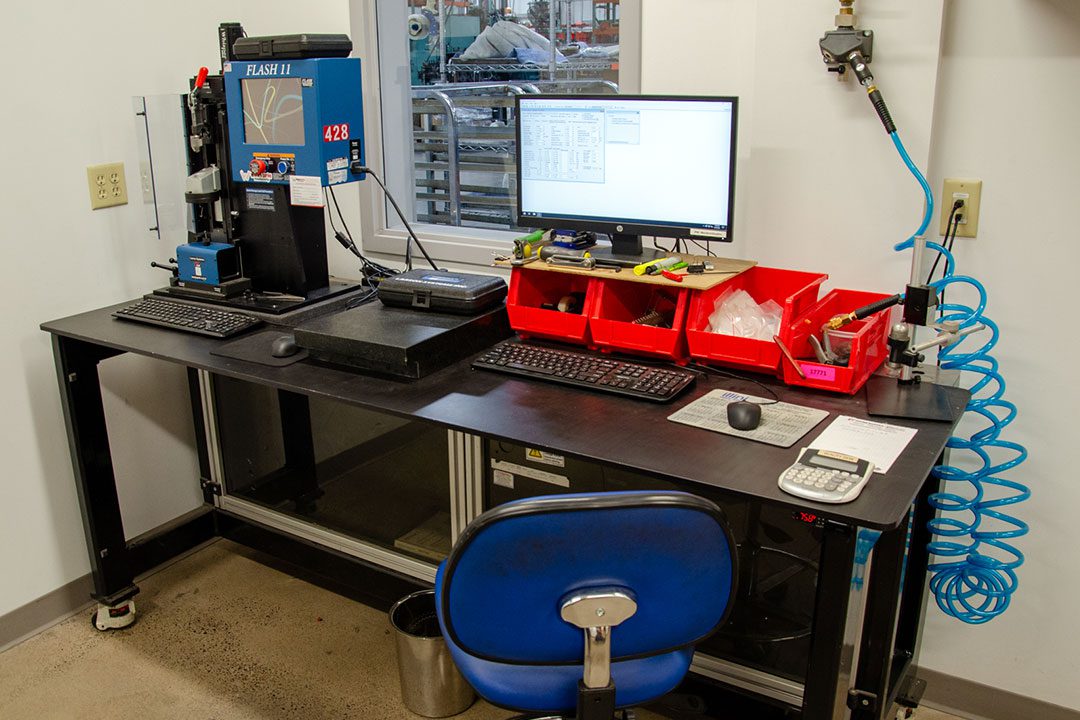

5. Stress Analysis and Quality Control:

Rigorous stress analysis during the design phase and quality control measures during manufacturing help identify and rectify potential defects, ensuring that the spring meets specified standards and requirements.

Testing parts is crucial to the process and our testing is above industry standard, ensuring that your parts are too.

6. Consistent Manufacturing Practices:

Consistency in manufacturing processes is critical. Variability in production can lead to inconsistent spring performance, affecting reliability across different units.

7. Proper Coil and Wire Treatment:

Ensuring uniformity in coil and wire treatment processes, such as shot peening or shot blasting, is essential to enhance the fatigue resistance and strength of the spring.

Our treatment processes are the best in the business, ensuring that your coils and springs are too.

8. Adherence to Industry Standards:

Following established industry standards and best practices in spring manufacturing helps guarantee that the final product meets required specifications and is reliable in its intended application.

We not only meet but exceed industry standards, our quality standards are part of the reason we have been in business so long. Good parts? No. Great parts.

9. Post-Manufacturing Inspection:

Implementing thorough inspection processes post-manufacturing, including non-destructive testing methods, allows for the identification of any defects or issues that may compromise the reliability of the spring.

At Western we meticulously inspect the springs that come through our line, looking and testing for anything that may be out of spec. We make sure the parts we ship are the highest quality.

Improve Spring Performance & Safety by Identifying Causes of Failure

By identifying and predicting the causes of spring failure, we produce better and more reliable products. At Western Spring, we are passionate about manufacturing only the highest quality springs so you can have the most reliable products possible.

Our engineering team works tirelessly to improve spring quality and we partner with you so that the life of the spring is second to none.

Contact us today to get your project off the ground or with any questions you may have, we’d be glad to help!