In the dynamic world of spring manufacturing, precision and reliability are paramount. Quality control processes serve as the foundation and help ensure that every spring meets industry benchmarks and surpasses customer expectations. Here at Western Spring Manufacturing, we go the extra mile to meet and exceed your expectations.

Western Spring Manufacturing: Precision Coil Springs Start with Quality People

From the time you contact us for a free estimate until the shipment leaves our facility, our highly trained employees have their eyes on every aspect of your product. As a family-owned company, our commitment to quality begins by choosing and training passionate people to maintain our level of excellence. This excellence doesn’t come from an office with measuring devices but rather a belief that every employee – from operator to quality control – has that results in the production of the very best springs and wire forms. We believe that Western Spring should produce a quality product for our customers every time.

In order to produce a quality product, the manufacturing processes and products must align with industry-specific standards and certifications. This not only assures quality but helps in establishing credibility within the industry. At Western Spring, our people are held to high standards to ensure we are a spring manufacturer capable of providing unparalleled results.

Documentation and Traceability: Key to Product Control

In spring manufacturing, meticulous documentation is the linchpin of quality control. From selecting raw materials to fine-tuning processes, every step of our process undergoes scrupulous documentation. This extends to in-run monitoring and final inspections, ensuring no detail escapes scrutiny. By chronically documenting every step, we enable seamless traceability; thus, documentation can be a powerful tool in the event of any quality concerns.

The precision and commitment to detail in documentation should also extend to all aspects of the production process. Here at Western Spring, we log and track every element, from wire form design to creating custom springs, allowing us to meet industry standards and help us set the bar for excellence.

The Core Processes: Elevating Spring and Wire Form Manufacturing Quality

Depending on a customer’s specific requirements, we offer diverse testing methods tailored to meet the highest industry standards. However, several core processes distinguish our quality control practices, thus ensuring that every spring we produce is of unmatched excellence.

Incoming Material Inspection: The Genesis of Quality

To ensure every product meets your exact needs and our standards, we not only work to hire the best staff for the job, but we strive to use the highest quality materials. Using the best quality materials helps us deliver consistent products and ensure you get a spring that meets your unique needs.

Steel wire and alloys undergo a scrupulous examination at Western Spring to ascertain their compliance with stringent specifications. This meticulous process comprehensively analyzes dimensions, chemical composition, and material hardness. Ensuring the integrity and performance of each spring are intrinsically linked to the quality of these foundational materials.

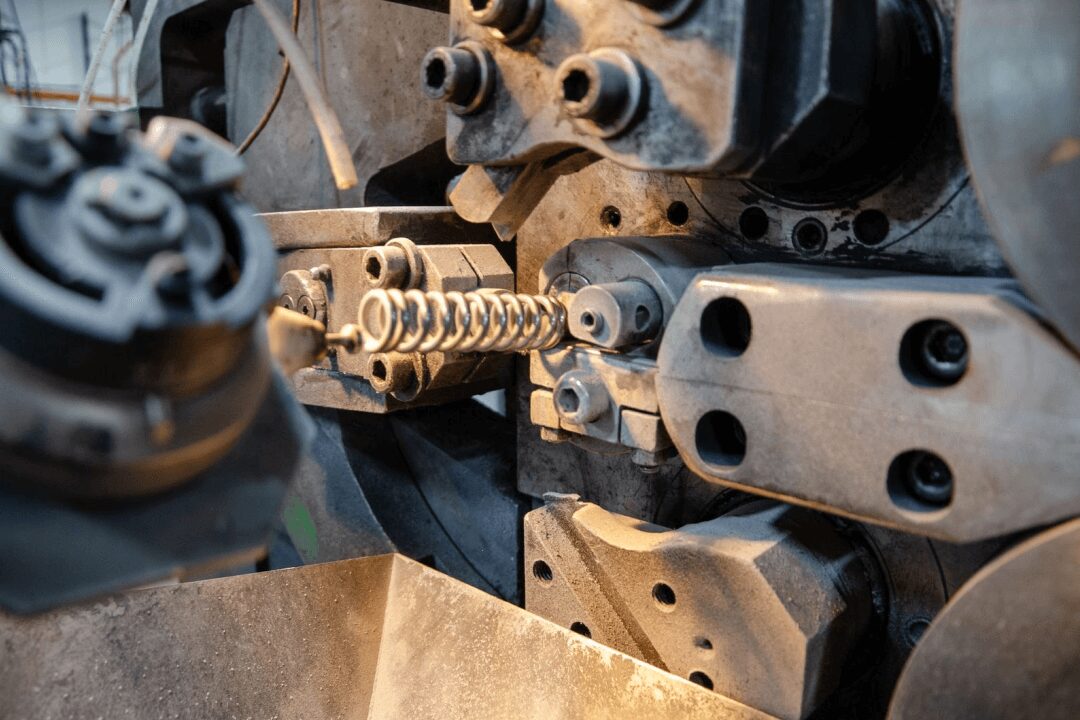

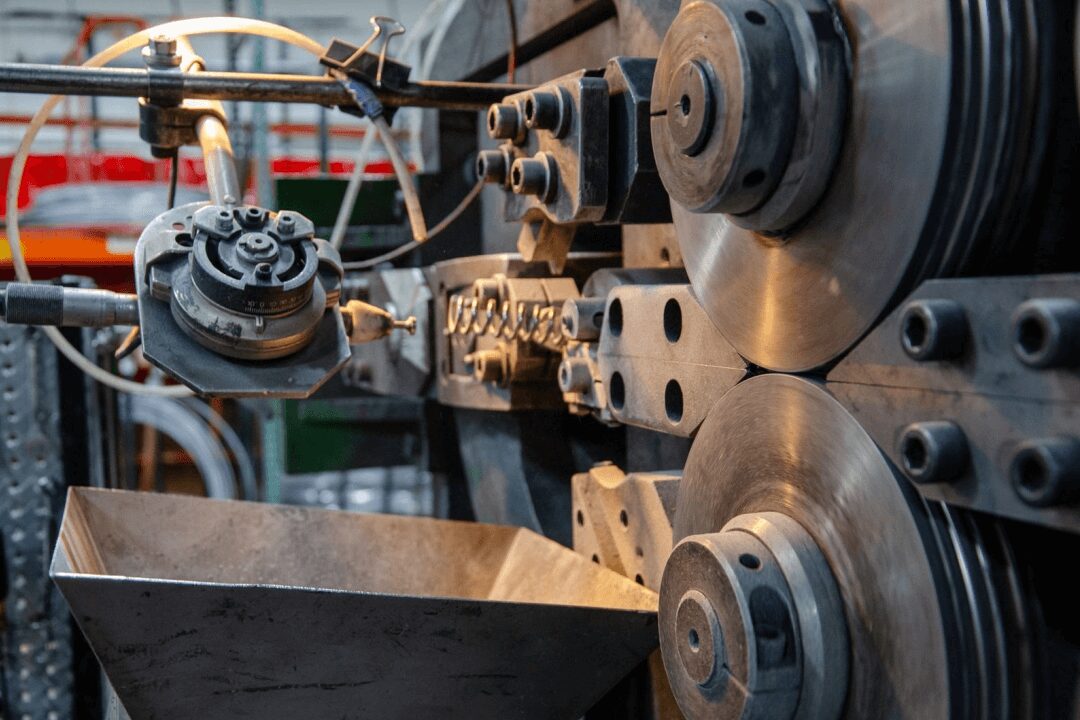

Production Process Monitoring: Precision in Every Coil

Throughout the custom manufacturing journey, unwavering vigilance prevails. Parameters such as wire diameter, free length, and stress relief are meticulously scrutinized. This stringent oversight ensures every spring meets your exact specifications and ours, thus helping us guarantee uniformity, durability, and reliability.

Dimensional Checks: Exacting Precision to the print specification

Finished springs also undergo a rigorous measurement process. Utilizing tools like calipers and micrometers leaves no room for deviation. Every spring is subjected to a thorough examination of its dimensions, ensuring that it is a testament to precision and accuracy.

Load Testing: Assessing Resilience Under Load

Another step we take to ensure each type of spring meets our standards is load testing. This testing serves as the primary measurement of a spring’s force at a given height. Applying controlled force, we meticulously measure the spring’s deflection and recovery. This critical process verifies the spring’s performance under demanding conditions, assuring reliability in real-world applications.

Fatigue Testing: Certifying Endurance Through Repetition

Certain applications also necessitate springs capable of enduring repeated cycles. Fatigue testing helps simulate conditions by rigorously assessing the spring’s ability to maintain durability over time. This step allows us to separate exceptional springs from merely adequate ones.

Surface Finish Inspection: Marrying Aesthetics with Functionality

While aesthetics may seem secondary, they hold immense significance. Regarding the aesthetic, each spring undergoes a comprehensive examination to detect imperfections such as cracks, burrs, or corrosion. Surface integrity is paramount, as blemishes could compromise the spring’s performance.

Stress Relief: Forging Strength and Elasticity

Stress relief is where raw materials metamorphose into resilient springs. Our quality control processes ensure that this critical phase is executed with surgical precision—the result: springs that embody the desired balance of hardness and elasticity.

Visual Inspection: The Invaluable Human Element

Our skilled inspectors, with keen eyes and extensive expertise, play a pivotal role in our quality assurance process. Inspectors visually scrutinize each spring to identify any imperfections and irregularities machines may overlook. This hands-on approach is an irreplaceable facet of our commitment to excellence and is one of the final steps in ensuring our commitment to quality and customers.

Packaging Inspection: The Final Seal of Approval

Finally, before any of our springs embark on their journey to our valued customers, they undergo a final inspection to ensure they meet every specification. This critical step guarantees the springs are prepared for seamless integration into their intended applications, reaffirming our commitment to delivering only the highest quality products that meet your specific needs.

Quality Control Facilities: Housing Top Quality Manufacturing Services

High-quality products require high-quality facilities and testing equipment. At Western Spring, we are at the forefront of manufacturing facility excellence. We understand that the working environment is often overlooked in quality control, but not here. Here, we take many steps to ensure our location is producing quality products that help us guarantee customer satisfaction.

From testing equipment placement to evaluating lighting so our expert employees have the right tools to craft the highest quality products, we constantly assess our environment to help us deliver the best product continuously. When customers order from Western Spring, they can rest assured that whatever spring they order for their next project, from automotive springs to medical devices, torsion springs to compression spring needs, vigorous testing is happening at every step of the process.

Elevating Excellence Through Continuous Improvement Testing

Excellence in manufacturing is a dynamic process, and at Western Spring, quality control is synonymous with precision and excellence. We are committed to a continuous pursuit of perfection. Our dedication to delivering the highest quality springs and wire forms goes hand-in-hand with our unwavering commitment to process improvement and incorporating new technologies.

People, Processes, and Facilities You Can Trust

In a world where detachment and automation are the norm, at Western Spring, we believe phenomenal customer service goes hand-in-hand with equipment operation and automation. Together, these things allow us to craft the best spring design.

If you have questions or want a free estimate, contact us any time. We look forward to finding the perfect solution for your unique application and aim to be completely accessible to you.