In the intricate world of valves and hydraulics, the unsung heroes often go unnoticed.

Customized compression springs play a pivotal role in ensuring the seamless functioning of various valve components and hydraulic systems. Here, we will look at the role of compression springs in valves and hydraulics, exploring their significance, manufacturing processes, and applications within the industry.

The Importance of Springs in Valve Systems

Valves, essential components in numerous industries, rely on springs for effective operation. These springs provide the necessary force to control the movement of valves, ensuring precision and reliability in diverse applications. From controlling fluid flow to managing pressure, springs are the silent workhorses behind the smooth functioning of valves.

In the realm of valves, a one-size-fits-all approach is seldom effective. Different spring applications demand distinct specifications, leading to the prominence of custom springs. Whether it’s a relief valve, control valve, or safety valve, the customization of springs ensures optimal performance tailored to specific requirements.

Applications of Hydraulic and Valve Springs

Hydraulic and valve springs are typically a mission critical component. Here are some of the many systems and industries in which hydraulic or valve springs have a crucial role.

- Automotive Industry:

In the automotive sector, hydraulic valve springs are integral components in internal combustion engines. They control the opening and closing of engine valves with precision, optimizing fuel combustion and power delivery. The demanding conditions of automotive environments highlight the need for reliable and durable springs to withstand constant cycles and varying temperatures. - Aerospace Technology:

Hydraulic and valve springs are crucial in aerospace applications, where precision and reliability are paramount. They find usage in hydraulic control systems for aircraft, regulating landing gear, wing flaps, and other critical components. The ability of these springs to maintain consistent force even in extreme conditions contributes to the safety and performance of aerospace systems. - Industrial Hydraulics:

In industrial settings, hydraulic systems are ubiquitous, powering heavy machinery and manufacturing processes. Hydraulic valve springs play a vital role in controlling the flow of hydraulic fluids, ensuring the precise movement of pistons and actuators. These springs contribute to the efficiency and accuracy of industrial processes, from metal stamping to plastic molding. - Oil and Gas Sector:

The oil and gas industry relies on robust and reliable equipment for exploration and extraction activities. Hydraulic valve springs are utilized in control valves that manage the flow of fluids in pipelines and drilling operations. The ability of these springs to withstand high pressures and harsh environmental conditions makes them indispensable in this challenging sector. - Medical Equipment:

In the realm of medical technology, precision is non-negotiable. Customized valve springs find applications in medical devices, such as infusion pumps and diagnostic equipment. These springs contribute to the accuracy and reliability of fluid control systems within medical devices, ensuring the safety and well-being of patients.

In each of these applications, hydraulic and valve springs provide crucial precision spring tension. Whatever your particular requirements, we can create a custom spring to meet your needs.

The Craft of Custom Spring Manufacturing

Manufacturing customized compression springs requires a delicate balance of precision and expertise. At Western Spring, we understand the nuances of the industry, utilizing state-of-the-art technology to produce springs with exact specifications. This precision engineering ensures that each spring meets the rigorous standards demanded by valve applications.

The material used in spring manufacturing is a critical factor. With the industry’s wide array of requirements, manufacturers often work with various alloys to meet specific needs. From automotive applications to electronics and beyond, the choice of alloy can significantly impact the performance and durability of the custom springs. Whatever your particular needs, we have the highest quality materials available for your spring manufacturing run or R&D project.

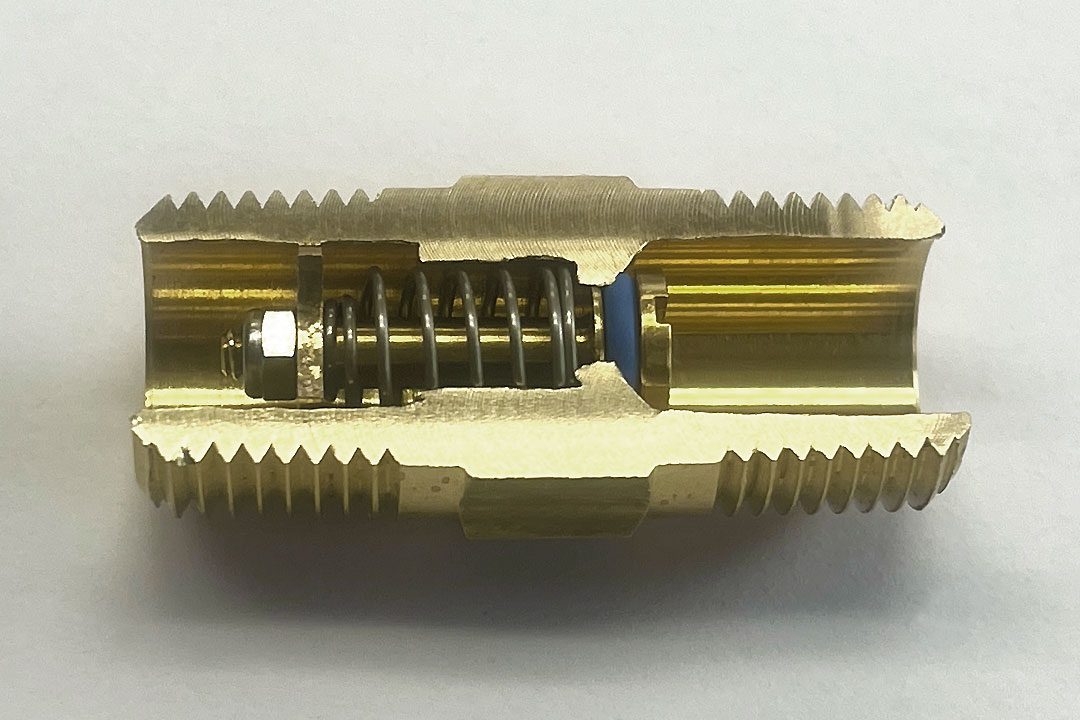

Custom Springs in Hydraulics and Valves

In the world of hydraulics, the need for precision is paramount. Customized compression springs find their niche in hydraulic valve systems, where they play a crucial role in controlling the flow of fluids. These springs ensure that valves open and close with the necessary force, maintaining the integrity of the hydraulic system.

Beyond hydraulic valve springs, custom springs find applications in an extensive range of valve components. Whether it’s extension springs for specific valve parts or torsion springs for intricate control mechanisms, the versatility of these springs makes them indispensable in the valve manufacturing industry.

Quality Manufacturing of Your Valve Springs

In an industry where precision is non-negotiable, the quality of custom springs is of paramount importance. At Western Spring, we adhere to the highest industry standards, employing rigorous quality control measures to ensure that each spring meets the required specifications. This commitment to quality is essential for the reliability and safety of valve systems and nothing less than the best will do for our

Custom springs are, by definition, tailored to specific customer needs. We specialize in custom springs and prioritize customer requirements, working closely with clients to understand their applications and designing springs that align with these unique specifications. This customer-centric approach sets us apart from other valve component manufacturers.

The Role of Compression Springs in Safety and Reliability of Valve Components

In applications where safety is paramount, such as relief valves and safety valves, the role of springs becomes even more critical. The precise calibration of these springs ensures that valves respond accurately to pressure changes, preventing potential hazards and ensuring the safety of the overall system.

Certain applications, especially those requiring a constant force, benefit from the use of constant force springs. These springs maintain a consistent force throughout their range of motion, offering a reliable solution for applications where variations in force could be detrimental.

Hydraulic Valve Springs: A Symphony of Precision and Functionality

In valves and hydraulics, customized compression springs play a crucial role, harmonizing precision and functionality. From the manufacturing floor to the intricate applications in various industries, these springs ensure that valves operate seamlessly, meeting the demands of a diverse and ever-evolving technological landscape. As industries continue to advance, the significance of custom springs in valve systems and hydraulics will undoubtedly persist, driving innovation and efficiency across the board.

At Western Spring, we create a wide range of valve component springs for a variety of applications. Feel free to contact us any time to request a estimate.