Embracing the Future of Manufacturing:

Automation in the Manufacturing Industry Springs Forward

The dynamic landscape of manufacturing is taking a significant leap into the future. With the convergence of cutting-edge technologies, automation is beginning to transform the manufacturing industry in ways never seen before.

Dive deep into the realms of automation, exploring its profound impact on manufacturing and the future of work. As you join us on this journey, we will unravel the potential benefits and advancements that spring forth from the integration of automation in the manufacturing sector.

What is the Role of Automation in Manufacturing?

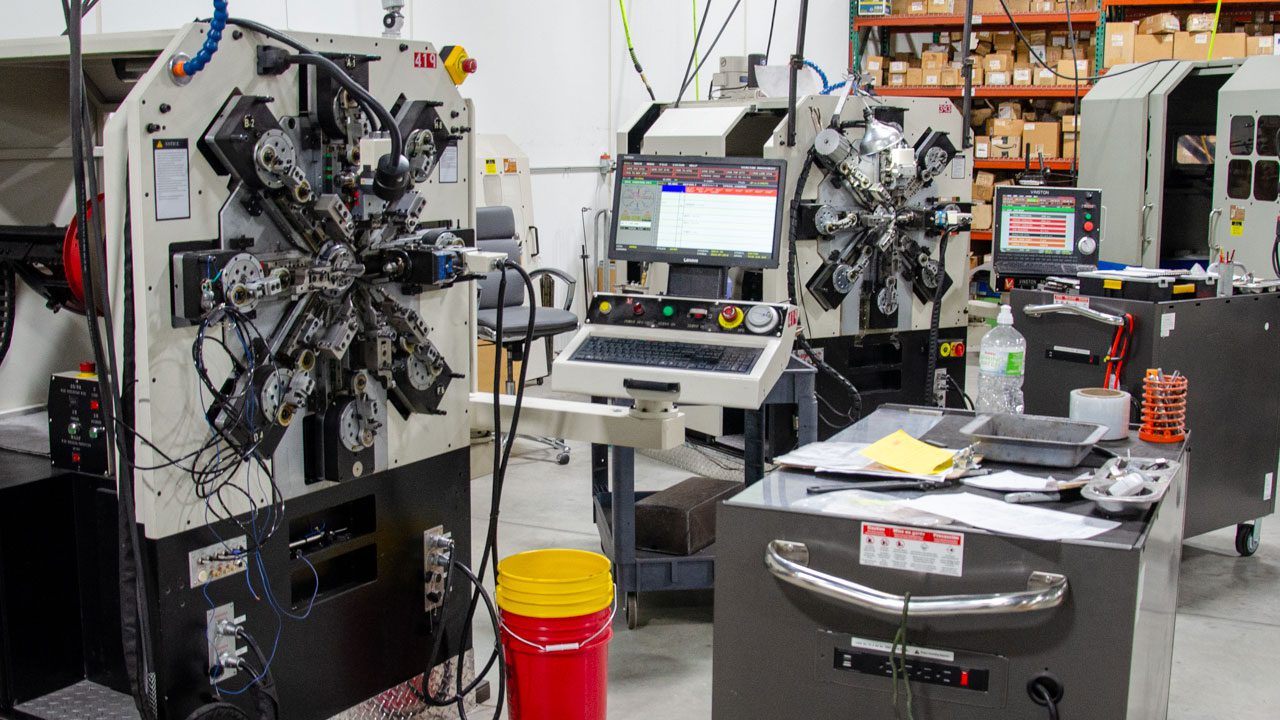

Automation involves using advanced machinery and control systems to perform tasks in the production process automatically, reducing the reliance on manual labor. The ability to automate can transform the production process, making it more efficient, precise, and scalable. As we step into the future, automation will become a pivotal force in the global manufacturing sector with the promise of unprecedented productivity as well as efficiency. At Western Spring, we have embraced the future of spring manufacturing and, with our manufacturing systems, can help our customers reach their goals.

How Can Automation Transform the Manufacturing Industry?

The integration of automation in manufacturing operations is not merely a trend but a fundamental shift that is set to redefine the industry. Automation empowers manufacturers to streamline their processes, optimize supply chains, and adapt to market conditions with agility.

By embracing automation, we can reduce costs, increase productivity, and produce higher-quality springs for you, the customer.

What Trends Define the Future of Work in Manufacturing?

To us at Western Spring, it is evident that the manufacturing landscape is on the brink of a transformational shift. The convergence of automation, AI, and IoT (Internet of Things) is creating a new paradigm where human workers collaborate seamlessly with automated machines.

This trend not only enhances productivity but also ensures worker safety, as robots can now handle tasks that are dangerous or monotonous.

How Does Automation Increase Productivity in Manufacturing?

Automation brings about a leap in productivity by taking over repetitive and time-consuming tasks. With the ability to work 24/7 without fatigue, automated machines drastically reduce production times and increase throughput. Moreover, the precision and accuracy they offer ensure products meet the highest standards, eliminating human error from the equation.

In 2023, Artificial Intelligence also plays a crucial role in manufacturing operations. It does so by providing real-time visibility into production environments, allowing for quick adjustments based on data-driven insights. By harnessing AI’s power, manufacturers are able to make informed decisions, enhance efficiency, and respond swiftly to changing market conditions.

Robotics and AI (Artificial Intelligence): Redefining the Factory Floor

Robotic systems equipped with AI capabilities are set to take center stage on the factory floor. These automated machines can autonomously handle complex tasks, working alongside human workers to accomplish feats that were once beyond human capability. This collaborative approach creates a leaner and more productive production environment.

Industry 4.0 and the Data Processing: A Symbiotic Relationship

The synergy between Industry 4.0 and modern data processing is poised to revolutionize manufacturing. The ability to gather and analyze vast amounts of data in real-time enables manufacturers to optimize processes, predict maintenance needs, and respond proactively to potential issues. This next-level connectivity empowers factories to operate at peak efficiency, which then turns into savings for our customers.

Conclusion: A Leap into the Future

As we journey into the next ten years, automation is starting to play a crucial role in the manufacturing sector. The integration of advanced technologies like AI, IoT, and AR promises to usher in a new era of productivity and efficiency. Embracing automation is not an option; it’s a strategic imperative for manufacturers looking to thrive in the ever-evolving global industrial landscape.

Here at Western Spring, we use automation to better serve our customers in their spring design and manufacturing needs.

- Automation increases productivity and efficiency in manufacturing operations.

- Robotics and AI collaboration redefines the factory floor, making it more productive and safe.

- Industry 4.0 and the Data Processing integration optimize processes and enhance operational efficiency.

- Augmented reality revolutionizes how workers interact with the manufacturing environment, reducing errors and increasing productivity.