At Western Spring Manufacturing, every custom spring begins with a commitment to quality and dimensional accuracy.

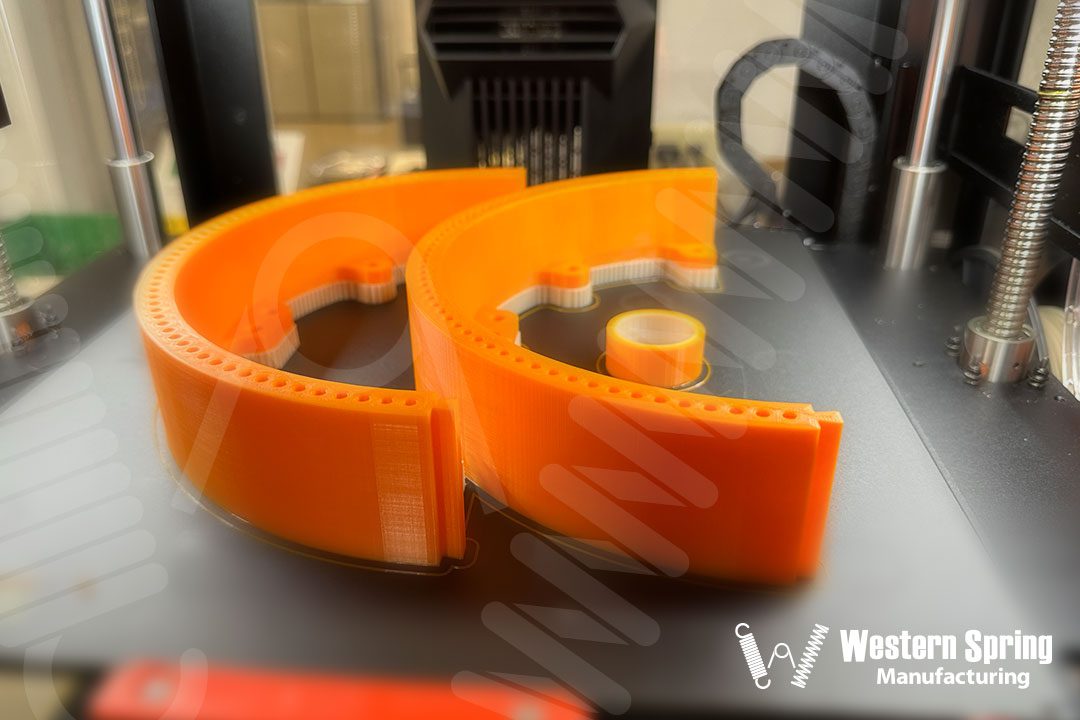

Behind each product lies a careful design and validation process supported by modern 3D modeling and printing techniques.

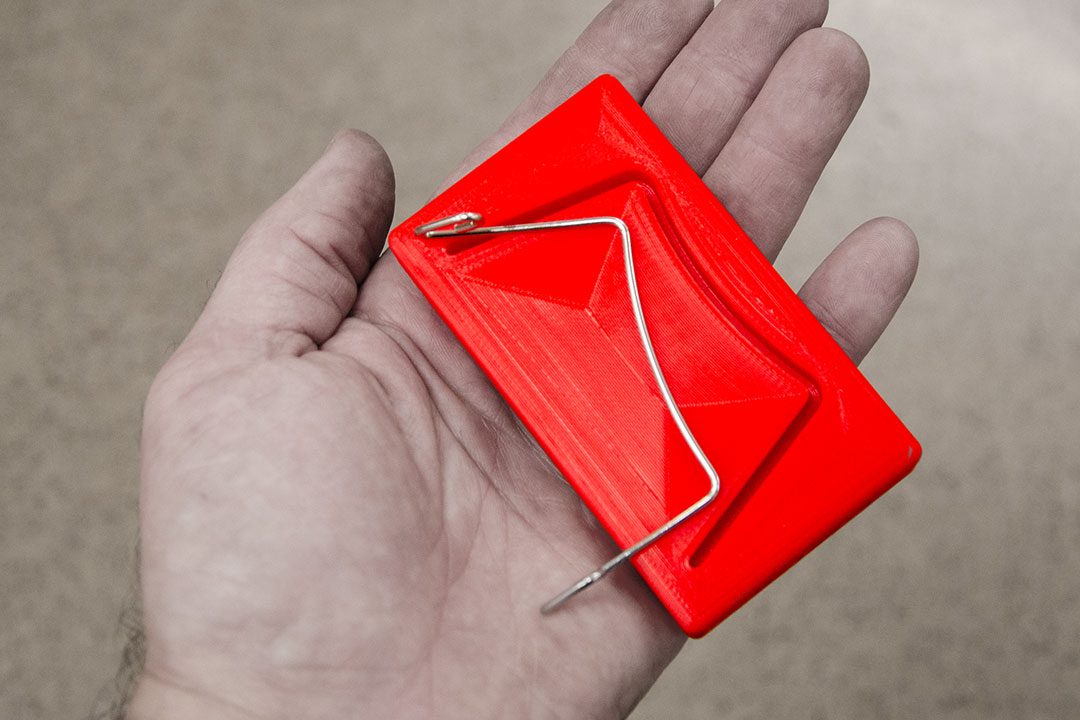

Another example of innovative tools used by Western Spring is a 3D modeled and printed “Go, No-Go” spring template. This custom fixture helps confirm whether every spring produced meets the required specification before it leaves the facility. Custom labeled with a Tool ID to match against the current print design, this template functions as both a precision tool and a reliable indicator of whether a spring meets tolerance limits.

Using this approach, Western Spring continues to merge traditional craftsmanship with cutting-edge modeling and metal fabrication techniques, ensuring consistent quality in every production run.

The Purpose of a Go, No-Go Spring Testing Tool

The Go, No-Go gauge is a quality control instrument used to test if a component’s dimensions fall within acceptable limits. For spring manufacturing, the concept is straightforward: the “Go” side allows the spring to fit if it meets the minimum dimension, while the “No-Go” side prevents fitting if the part exceeds the maximum tolerance.

This simple gauge gives instant feedback on whether the product conforms to its dimensional requirements. Instead of relying solely on complex measurement tools, this method offers a fast and repeatable testing solution for production teams. Western Spring enhances this principle by using 3D printed materials based gauges custom-designed for each spring type, maintaining accuracy and control across the production line.

Integrating 3D Modeling Into Spring Quality Testing

Western Spring’s in-house design specialists use CAD modeling to create a three-dimensional simulation of the Go, No-Go template before it is printed. The model replicates the exact geometry of the customer’s spring, reflecting every design parameter needed for accurate validation. Using 3D modeling allows engineers to visualize how the tool will interact with the spring and make real-time adjustments during the development process.

Once finalized, the gauge is 3D printed using durable, materials capable of holding tight tolerances. This approach not only speeds up prototype creation but also ensures consistency across testing tools. With each iteration, the design team can analyze dimensional behavior and validate performance before it reaches the production floor.

How the Template Improves Design Accuracy

A major advantage of using a 3D printed Go, No-Go template lies in its ability to validate geometry and maintain control over precision. Each template serves as a physical representation of the digital model, transforming CAD data into a tangible testing tool. This connection between design and physical testing closes the feedback loop, ensuring that every custom spring is built to exact specification.

The combination of 3D simulation and physical testing creates an integrated quality assurance system. Western Spring’s engineering team can easily identify deviations early, reducing costly rework and enhancing overall reliability.

Real-World Benefits of Custom 3D Printed Gauges

The benefits of using a 3D printed Go, No-Go gauge extend far beyond the production floor.

- Faster development time:

Engineers can quickly modify or reproduce gauges as client requirements change. - Greater repeatability:

Using the same template across batches guarantees consistent quality testing. - Reduced downtime:

When testing tools can be printed in-house, lead times shrink dramatically. - Customer Approval:

Testing tools are kept in-house and provided to customers for their own review process.

Each template reflects a customer’s unique spring design, providing the highest level of dimensional validation possible for that component.

Integrating Design Assistance and Advanced Testing

For companies that need support with spring design, Western Spring’s Design Assistance service helps translate ideas into manufacturable solutions. Combining digital modeling with 3D printing enables the team to create a virtual-to-physical validation process. Once the CAD model is complete, it moves to the testing stage, where the printed template becomes the primary validation tool.

By using this hybrid approach, Western Spring ensures dimensional consistency and mechanical performance before large-scale production begins. The company’s ability to model, validate, and test quickly helps clients bring new designs to market faster while maintaining precision and quality.

Why 3D Model Testing Matters to Service Providers and Customers

The integration of 3D modeling and physical validation provides measurable benefits for both Western Spring and its service providers. By maintaining consistent geometry through each stage of production, they help reduce waste, speed up project timelines, and deliver higher-quality results to customers.

Service providers in industries like automotive and defense applications depend on precision components, and Western Spring’s investment in advanced testing technology reinforces its role as a trusted partner. Through this method, clients gain confidence knowing their parts meet exact standards of dimensional accuracy and strength.

Maintaining Quality and Control at Every Step

Quality control at Western Spring isn’t just a step in production, it’s built into every phase of the design process. By using custom 3D modeled tools as part of its daily operations, Western Spring maintains complete oversight of dimensional performance.

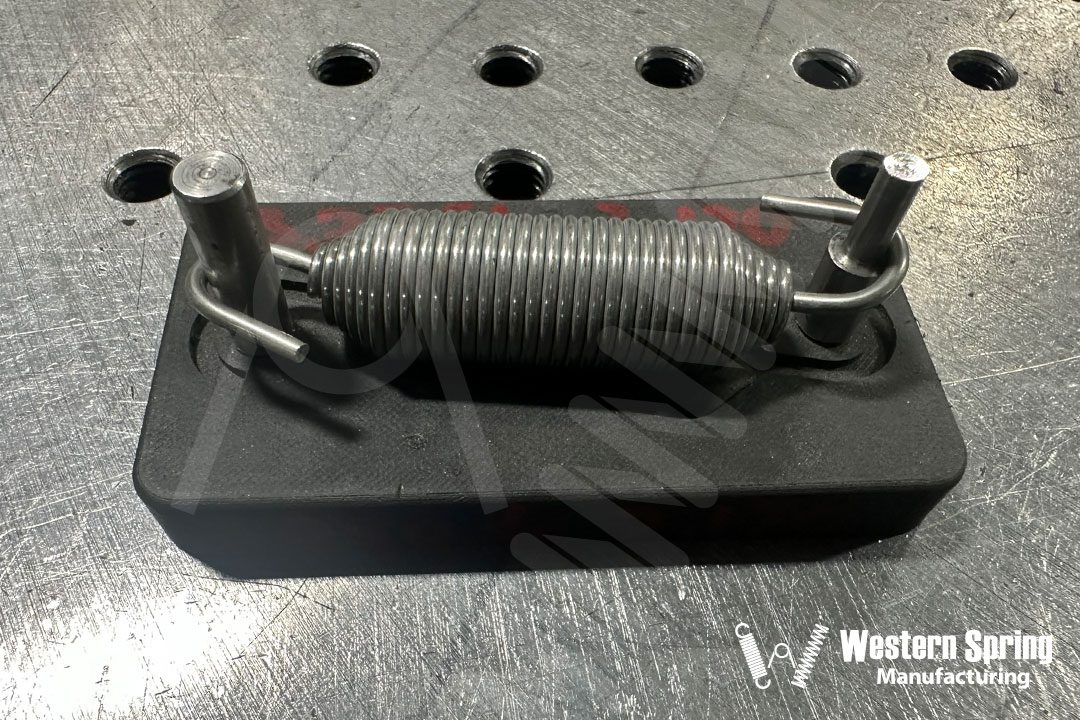

This process helps maintain control over accuracy in both prototype and production environments. Whether crafting springs for sensitive medical devices or robust industrial machinery, each product undergoes thorough validation to ensure precision and reliability.

Learn more about Spring Treatments and Finishing Options that complement this testing method.

From Design to Production: The Future of Custom Testing

Western Spring continues to push the boundaries of innovation by merging 3D modeling and printing with traditional manufacturing expertise. The ability to quickly produce and validate custom Go, No-Go gauges ensures that the design intent is preserved from the digital model to the final spring.

This combination of modeling, testing, and validation supports the company’s mission to produce superior springs while improving efficiency for every client. For those developing new applications that require custom components or advanced dimensional validation, Western Spring’s approach delivers unmatched reliability. Visit Services to explore how this technology fits into the broader design and testing process or review available Spring Products to find the right fit for your project.

Partner With Western Spring for Precision and Performance

When your project demands perfect requirements and measurable accuracy, Western Spring Manufacturing is the partner you can rely on.

Their innovative use of 3D printed Go, No-Go templates ensures each spring undergoes complete testing and validation. Whether you’re beginning a new design or refining an existing component, their engineers are ready to collaborate from CAD modeling through final quality control. To start a conversation, Request an Estimate or Schedule a Meeting with their team today.

Experience how modern design tools and three-dimensional testing methods maintain unmatched quality and reliability across every spring they produce.