Canted coil springs—also referred to as wire wound springs, slant springs, or seal springs—are an advanced form of spring technology designed to deliver near constant spring force across a wide deflection range.

These springs play a critical role in sealing applications, electrical connectors, EMI shielding, and precision engineering where consistency, reliability, and material integrity are essential. In this article, you’ll discover how canted coil springs work, why industries rely on them, and how their unique design offers benefits that traditional compression springs or helical springs cannot match.

Western Spring Manufacturing, a fourth-generation family-owned manufacturer, specializes in producing custom springs for demanding industries like aerospace, medical, automotive, and industrial applications. Their expertise in engineering canted coil springs and spring-energized seals ensures that clients receive high-performance components tailored to their exact needs, enhancing the overall integrity of data.

What is a Canted Coil or Slant Coil Spring?

Canted coil springs are engineered springs made of individual coils slanted at an angle. This “cant” in the coil design creates a spring force that remains predictable and repeatable across the entire deflection range. Unlike standard helical springs, which increase in force the more they compress, a canted coil spring maintains a near constant spring force. This makes them ideal for precision applications such as sealing, latching, and electrical contact, particularly in axial configurations.

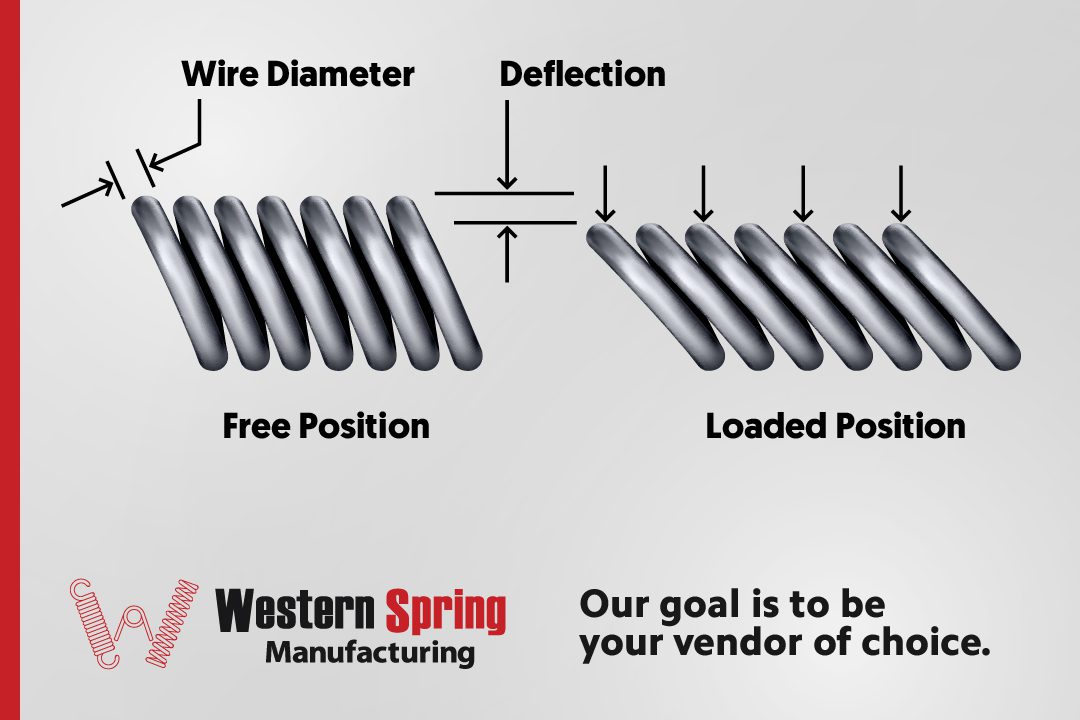

“Deflection range” refers to the maximum acceptable amount of bending or deformation that a structural element or system can undergo under a given load.

The coils can be manufactured from stainless steel, 302 stainless, or advanced alloys like Inconel and Hastelloy for corrosion resistance. In many applications, canted coil springs are combined with a polymer jacket to create spring-energized seals that improve sealing performance in demanding industries like aerospace and downhole tools.

How Does the Cant Affect Spring Force?

The cant in the spring coil alters the load curve, which is critical for optimizing spring energized designs. Instead of a steep rise in force like a compression spring, canted coil springs offer a flat load curve, delivering near constant spring force. This is highly beneficial in sealing applications where predictable loads and reliable operation are essential, especially for spring energizers. The cant also minimizes compression set, ensuring springs maintain their performance over time.

Western Spring Manufacturing engineers use advanced spring design software and testing equipment to verify the force/length characteristics of each spring. This level of precision ensures predictable performance and repeatable results in every custom design.

What Materials are Used in Canted Coil Springs?

Material selection plays a crucial role in spring performance. Common materials include stainless steel for corrosion resistance, 302 stainless for reliable performance, and high-strength alloys like MP35N or Beryllium Copper for electrical conductivity. Coatings and plating options, such as nickel or chrome plating, add further protection in corrosive applications.

Western Spring Manufacturing offers customization in wire diameter, coil spacing, and coil height to ensure each spring meets the required specifications. Their ability to produce custom sizes and finishes makes them a trusted manufacturer for diverse industries.

What Applications Benefit Most from Canted Coil Springs?

Canted coil springs excel in applications requiring consistent spring force and multi-point contact. Common uses include:

Sealing Applications:

Spring-energized seals rely on canted coil springs to energize a polymer jacket, providing reliable sealing under pressure.

Electrical Connectors:

They deliver low contact resistance and EMI shielding, protecting sensitive equipment from crosstalk and interference.

Latching Systems:

Canted coil springs provide repeatable latch force for mechanical and electrical devices.

Aerospace and Downhole Tools:

High-load, corrosive, and space-limited environments where less space and safety are critical.

How Do Radial Canted Coil Spring Seals Work?

A canted coil spring seal, sometimes referred to as a spring-energized seal, uses a polymer jacket that is energized by the spring. The spring applies consistent radial force against the mating surface, ensuring reliable sealing even under heavy load or high pressure. This technology is ideal for industries where seal integrity and equipment reliability are paramount.

Western Spring manufactures canted coil spring seals with precise cross-section geometry to guarantee proper sealing performance. These seals are widely used in medical equipment, aerospace assemblies, and industrial enclosures.

What is the Cross-Section Design of a Canted Coil Spring?

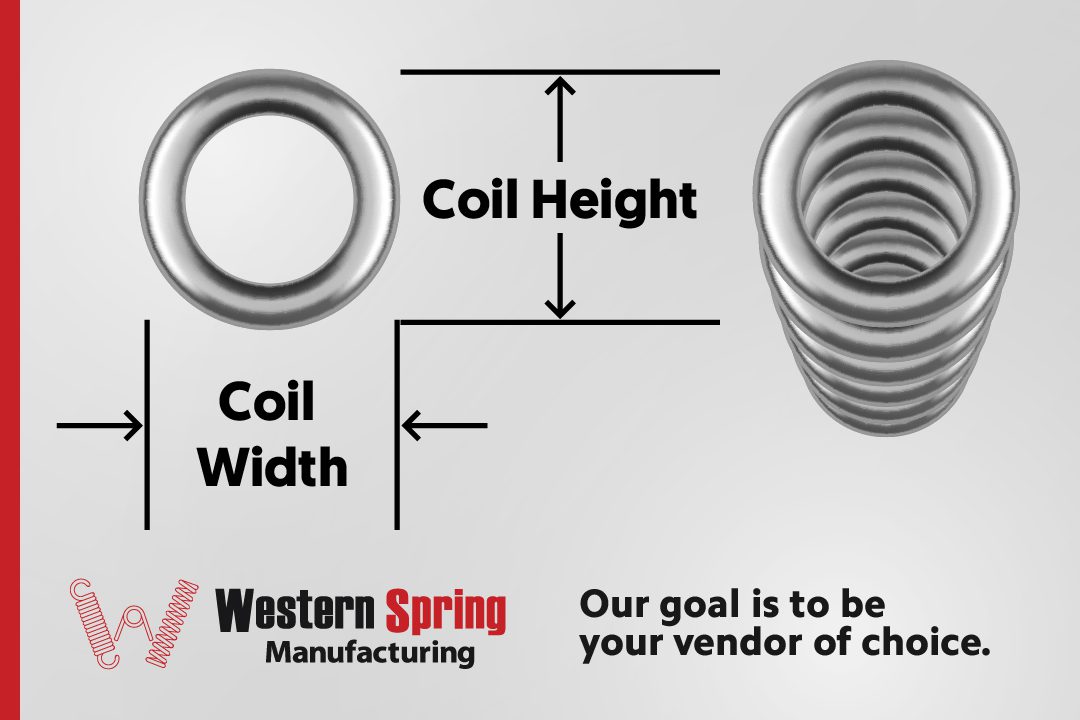

The cross-section of a canted coil spring determines how it distributes load, affecting the insertion and removal forces during operation. Variations in coil spacing, wire diameter, and coil height affect the spring’s deflection ability and performance. Engineers may choose tighter coil spacing for high load capacity or wider spacing for flexibility.

Western Spring’s engineers provide design assistance to help clients choose the right cross-section for their application, minimizing the risk of interference and maximizing performance.

What Are the Benefits of Wide Deflection Range?

One of the greatest advantages of canted coil springs is their wide deflection range, making them suitable for various fastening applications. This means the spring can be compressed or deflected significantly without losing performance. The wide deflection range ensures that the spring maintains predictable loads and near constant spring force across various positions.

Industries benefit from this because it reduces wear, extends the service life of seals, and minimizes equipment downtime. Western Spring Manufacturing’s testing capabilities guarantee that springs meet the required deflection specifications before deployment.

How Do Plating and Coatings Improve Performance?

Plating, such as nickel or chrome, improves corrosion resistance and enhances electrical conductivity. This makes plated canted coil springs highly effective in EMI shielding applications where electrical properties are crucial.

Western Spring Manufacturing provides plating options and additional finishing treatments such as electropolishing, passivation, shot peening, and vibratory finishing. These ensure the right balance of corrosion resistance, fatigue strength, and surface finish for each application.

Why Choose Customization in Canted Coil Springs?

Every application requires unique spring performance. Customization in coil spacing, coil height, and wire diameter ensures that each spring delivers effective compression. Custom sizes and laser welded options can be produced by Western Spring to fit exact client specifications.

This flexibility makes Western Spring Manufacturing a trusted partner for industries requiring specialized solutions. Their focus on repeatable manufacturing processes ensures consistent performance across all custom designs.

Summary: Key Points to Remember About Canted Coil Springs

- Canted coil springs are also called wire wound springs, slant springs, and seal springs.

- They provide near constant spring force across a wide deflection range.

- Common materials include stainless steel, 302, and advanced alloys with plating options.

- Applications include sealing, latching, electrical connectors, and EMI shielding.

- Canted coil spring seals use a polymer jacket energized by the spring for superior sealing.

- Western Spring Manufacturing specializes in custom canted coil springs for aerospace, medical, automotive, and industrial industries.

- Customization in design ensures predictable loads, and minimized equipment failure.

For more information or to request design assistance,

visit Western Spring Manufacturing’s Design Assistance page or Request an Estimate.